8 Series

4

Factors Affecting Flame

Arrestor Performance

Gas Group

WARNING

!

Methanol is classified by the National

Electrical Code (NEC) as a Group-D

vapor. However, our lab tests indicate

that methanol exhibits characteristics

unlike other Group-D vapors under

certain conditions. We therefore

recommend that an arrestor rated

for Group-C vapors be specified for

methanol service.

The type of gas in the system determines its gas

grouping and therefore predetermines the type of

arrestor element required. The element must be

designed to accommodate the specific gas group that

could possibly ignite and propagate in the system. The

more explosive gases require the flame cell to absorb

the heat more quickly and efficiently. The National

Electrical Code (NEC) groups gases into A, B, C, D

and G.M. categories depending on the Maximum

Experimental Safe Gap (MESG) of the gas.

Maximum Experimental Safe Gap

(MESG)

WARNING

!

Verify that the high pressure deflagration

flame arrestor being installed has the

appropriate gas group rating for your

process. This information is shown on

the nameplate attached to the element

housing. Do not remove or alter

this nameplate.

The measurement of the maximum gap between two

equatorial flanges on a metal sphere that will prevent

a flame from being transmitted from the sphere to the

surrounding flammable mixture. MESG is dependent

on gas composition. The stochiometric mixture (the

ideal air/fuel ratio for the most efficient combustion)

is used to determine the minimum MESG for a

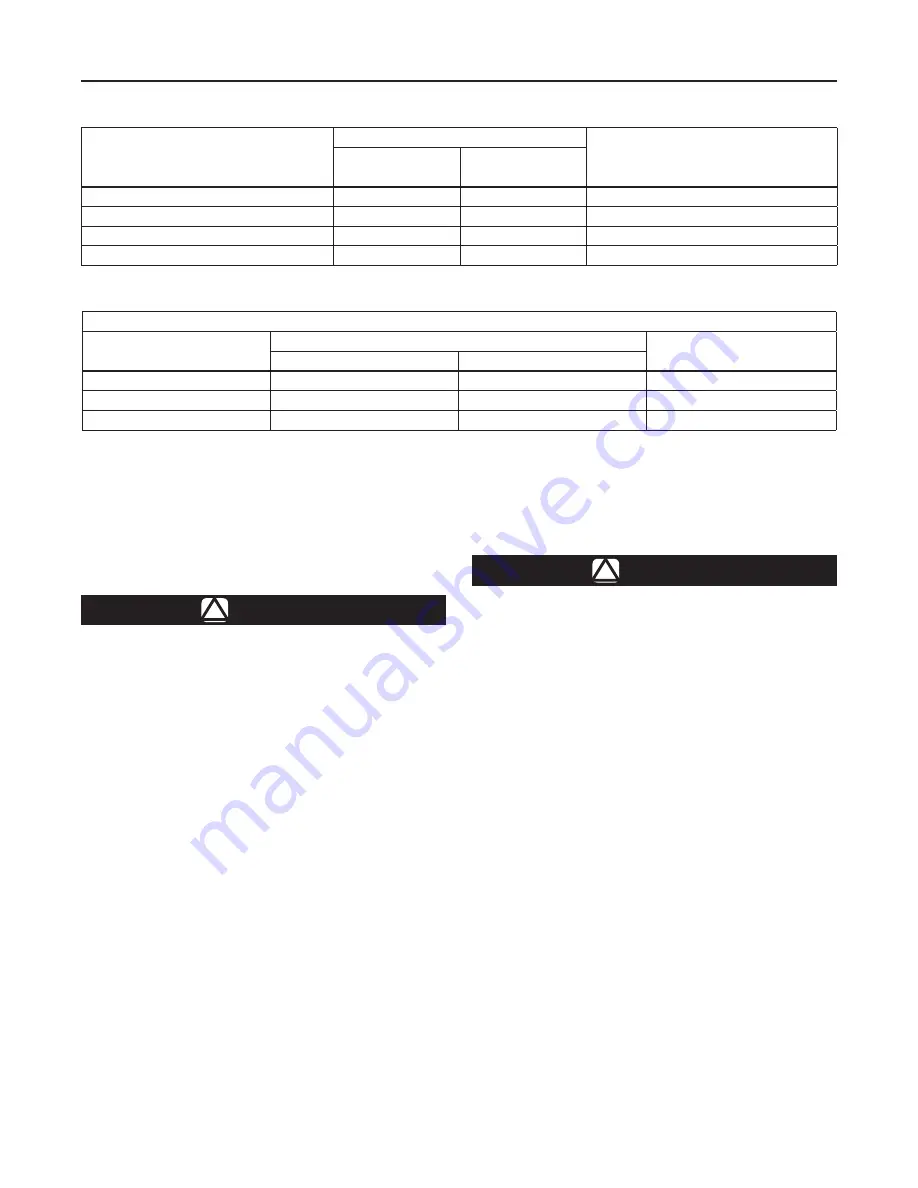

given gas. See Table 2 for the MESG per gas group.

Table 2.

Maximum Experimental Safe Gap (MESG)

NATIONAL ELECTRIC CODE (NEC)

MESG

TEST GAS LIST

In.

mm

Group B

0.011

0.28

Hydrogen

Group C

0.026

0.65

Ethylene

Group D

0.035

0.90

Propane

G.M.

0.044

1.12

Methane

HIGH PRESSURE DEFLAGRATION FLAME ARRESTORS - ALL SIZES

Gas Group

Maximum Initial Pressure

Endurance Burn Time

psia

kPa

D

19.7

136

15 Minutes

C

16.7

115

15 Minutes

B

16.7

115

5 Minutes

Table 3.

8 Series High Pressure Deflagration Flame Arrestor Endurance Burn Time