AE4-1322

© 2002 Copeland Corporation

Issued 4-2002

Printed in U.S.A.

16

6.2 Selection of electrical components

6.2 Selection of electrical components

6.2 Selection of electrical components

6.2 Selection of electrical components

6.2 Selection of electrical components

Cables, contractors and fuses

Cables, contractors and fuses

Cables, contractors and fuses

Cables, contractors and fuses

Cables, contractors and fuses

CAUTION

CAUTION

CAUTION

CAUTION

CAUTION

Nominal power is not the same as

Nominal power is not the same as

Nominal power is not the same as

Nominal power is not the same as

Nominal power is not the same as

maximum motor power! When selecting

maximum motor power! When selecting

maximum motor power! When selecting

maximum motor power! When selecting

maximum motor power! When selecting

cables, contactors and fuses:

cables, contactors and fuses:

cables, contactors and fuses:

cables, contactors and fuses:

cables, contactors and fuses: Maximum

Maximum

Maximum

Maximum

Maximum

operating current / maximum motor

operating current / maximum motor

operating current / maximum motor

operating current / maximum motor

operating current / maximum motor

power must be considered. See chapter 8.

power must be considered. See chapter 8.

power must be considered. See chapter 8.

power must be considered. See chapter 8.

power must be considered. See chapter 8.

Contactor selection: according to

Contactor selection: according to

Contactor selection: according to

Contactor selection: according to

Contactor selection: according to

operational category

operational category

operational category

operational category

operational category AC 3.

AC 3.

AC 3.

AC 3.

AC 3.

Part winding motors

Part winding motors

Part winding motors

Part winding motors

Part winding motors

The following current values appear in the part wind-

ings:

PW1

PW2

50%

50%

Both of the contactors should be selected for at least

60% of the maximum operating current.

Star delta motors

Star delta motors

Star delta motors

Star delta motors

Star delta motors

Calculate mains and delta contactor each to at least

60%, start contactor to 33% of the maximum operating

current.

Power factor correction

Power factor correction

Power factor correction

Power factor correction

Power factor correction

For the reduction of the reactive current when using

inductive loads (motors, transformers), power factor

correction systems (capacitors) are increasingly being

used. However, apart from the undisputed power

supply advantages, experience shows that the layout

and execution of such systems is not a simple matter,

as insulation damage on motors and increased contact

arcing on contactors can occur.

With a view to a safe operating mode, the correction

system should be designed to effectively prevent “over-

correction” in all operating conditions and the uncon-

trolled discharge of the capacitors when starting and

shutting down the motors.

General design criteria

General design criteria

General design criteria

General design criteria

General design criteria

•

Maximum power factor (P.F. 0.95 - taking into

consideration all load conditions.)

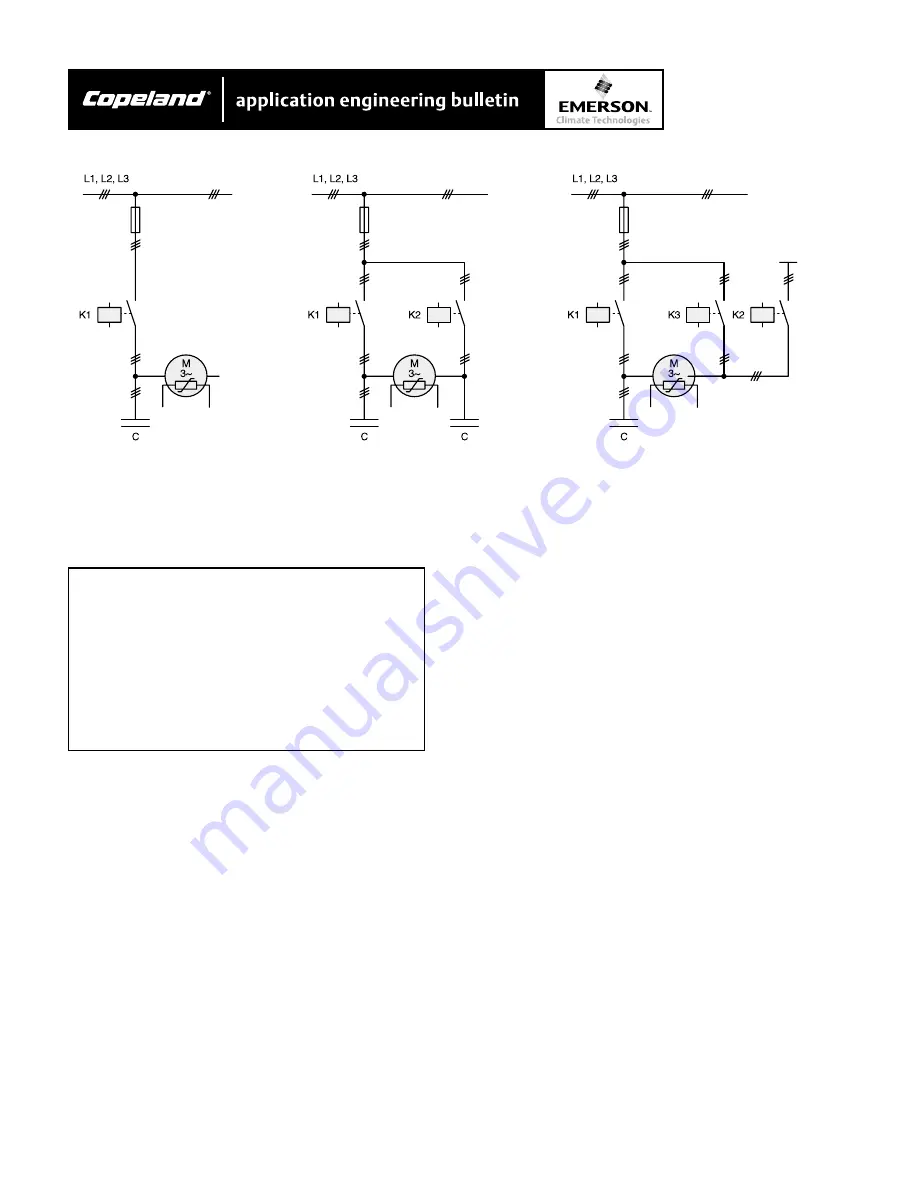

Individual correction (Fig. 21)

Individual correction (Fig. 21)

Individual correction (Fig. 21)

Individual correction (Fig. 21)

Individual correction (Fig. 21)

•

With capacitors that are directly fitted to the motor

(without the possibility of switching off with

contactors), the capacitor capacity must never be

greater than 90% of the zero-load reactive capacity

of the motor (less than 25% of max. motor power).

With higher capacities there is the danger of self-

exiting when shutting off, resulting in damage to the

motor.

Figure 18

Power factor correction on individual compressors