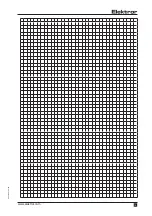

14

U

B

0

f

B

Prohibited

range

www.elektror.com

Operating and assembly instructions A-HP

9025316 07.20/05

EN

frequency converter (provided that this is suitable) it is es-

sential that the EMC instructions from the frequency convert-

er manufacturer and the information in the Elektror operating

and assembly instructions are observed in order to meet the

requirements of the EC “Electromagnetic Compatibility” Di-

rective 2014/30/EU.

If the device is delivered together with a frequency converter

package for switch cabinet or wall mounting closer to the mo-

tor, it is possible to comply with EN 61800-3 category C2 (In-

dustrial environments), taking into consideration the above-

mentioned EMC instructions.

Warning!

This product may cause high-frequency inter-

ference in a residential environment that may

require screening measures.

Blowers with an in-built frequency converter (FUK):

Devices with an in-built frequency converter meet the re-

quirements of the EC “Electromagnetic Compatibility” Direc-

tive 2014/30/EU under consideration of EN 61800-3 Catego-

ry C2 (industrial environment), taking into account the EMC

instructions from the frequency converter and the information

in the Elektror operating and assembly instructions.

Warning!

This product may cause high-frequency inter-

ference in a residential environment that may

require screening measures.

A CE conformity assessment with the relevant standards and

guidelines must be carried out in all cases before the start-

up.

4 INSTRUCTIONS FOR OPERATION

AND USE

4.1 Basic information

Please observe the notes on designated use in section 1.1,

as well as the safety guidelines in sections 1.2 to 1.14.

If electrical current drops below the rated current of the drive

motor during operation, check to see if the mains voltage and

frequency match the appliance ratings.

After protective shutdowns, e.g. tripping of the motor circuit-

breaker, activation of the PTC evaluation unit by motors with a

PTC resistor sensor, or after a protective shutdown of the fre-

quency converter during FU applications, the appliance must

not be restarted until the problem has been troubleshooted.

If the blower cannot be operated over the whole range of the

characteristic curve, the motor may overload if the system

resistance is too low (excessive current consumption). The

volumetric air

fl

ow should be reduced in this case by means

of a throttle valve

fi

tted on the intake or discharge side.

The blower must not be subjected to vibration or impact loads.

4.2 Frequency converter operation

A frequency converter is used, allowing a wide range of

speed adjustments. There is only a small, load-related dif-

ference in rpm between idle state and the max. load of the

blowers and the lateral channel blower.

To ensure trouble-free operation of blowers and side

channel blowers, it is important that the converter meet

the following requirements:

• Converter output equal to or greater than motor power

output *)

• Converter current equal to or greater than motor current *)

• Converter output voltage equal to rated motor voltage

• Supply voltage max. 480V, including 5% voltage tolerance

• The pulse frequency of the converter should be 8 kHz,

because a lower pulse frequency will lead to noisy motor

operation

•

The values for the maximum/minimum frequency can be

found at 1.10.

• The converter should have a connection for a tempera-

ture sensor (PTC resistor sensor) or a temperature switch

(normally-closed contact)

*) Refer to the rating plate for data

The motor can be operated in a delta or star-point con

fi

gura-

tion, depending on the input voltage of the converter.

The following U/f assignments must be con

fi

gured at the

converter.

f

B

and U

B

= refer to rating plate

If this is ignored, the motor current will increase dispropor-

tionately and the drive motor will fail to achieve its rated

speed.

Warning!

To avoid personal damage, destruction of the

blower or motor overload, a higher frequency

(speed) than the frequency (f

B

) speci

fi

ed on the

rating plate must never be set on the converter

otherwise the motor may be overloaded or the

blower destroyed due to the increased speed. The

temperature sensors are connected to the corre-

sponding converter inputs to protective the drive

motor. Single-phase alternating current motors

are not suitable for converter operation.

It is absolutely essential that you observe the

installation and safety instructions described in

the respective operating or application manuals

provided by the frequency converter supplier to

guarantee a safe and trouble-free operation.

It is also important to note that special ambient

conditions may lead to a high level of contamina-

tion of the cooling

fi

ns with the FUK devices. The

frequency converter switches o

ff

if the cool-

ing output on the cooling

fi

ns is not adequate.

Regular cleaning is required for devices in these

environments.

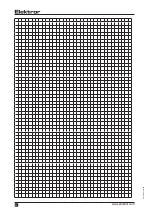

Note!

The following times apply for the respective

device motor output class (see rating plate) with

run-up/expiry as well as speed changes in order

to avoid high component loads and faults in the

converter operation:

Device motor output

Run-up time

[s]

Expiry time

[s]

0,25 kW < Motor output <=

3,0 kW

10

20

3,0 kW < Motor output

<= 7,5 kW

20

40

7,5 kW < Motor output

<= 11,0 kW

30

60

Содержание A-HP

Страница 19: ...19 www elektror com 9025316 07 20 05 ...

Страница 24: ...24 www elektror com 9025316 07 20 05 ...

Страница 25: ...25 www elektror com 9025316 07 20 05 ...