Maintenance

continued

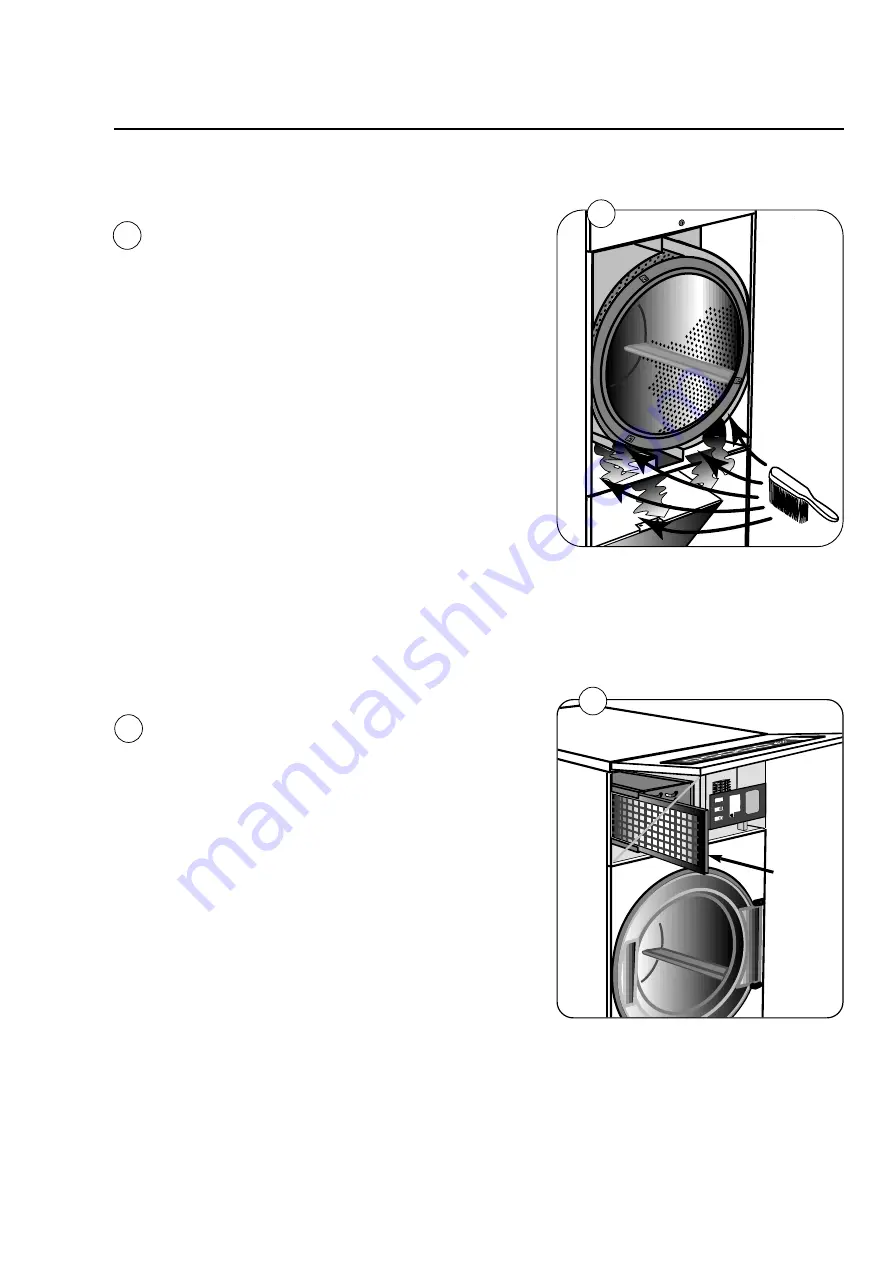

Annually

• Check that the fresh-air intake to the room and

evacuation ducts/pipes in and from the room is not

clogged by lint or dust or otherwise blocked.

Carry out cleaning/cleansing at a frequency that

depends on the operating load - once a year as a

minimum.

• Dismount front panel and finger protector.Clean for

lint/dust

• At least once a year a skilled expert should check

the inside wearing parts of the machine and clean

them of lint.

Lubrication

The motor bearings, idler bearings, and main

bearings are permanently lubricated.

No lubrication is necessary

Maintenance only for steam heating

Cleaning the filter in front of steam battery

• Open the front panel.

• Remove the filter as shown (A).

• Clean the filter with water or with compressed air.

• Replace the filter and close front panel

The filter ought to be cleaned at least once a week.

Instructions for use

17

487 18 39 01 - 300/500/750 - GB

A

1

1

4

1

4

1

Содержание TT300

Страница 1: ...Operating and installation manual TT300 TT500 TT750 487 1839 51 01 99 31 ...

Страница 2: ......

Страница 4: ......

Страница 6: ......

Страница 18: ...Instructions for use 18 487 18 39 01 300 500 750 GB ...

Страница 26: ...General installation 487 18 39 01 300 500 750 GB 26 ...

Страница 38: ...Installation electric steam and gas heating 487 18 39 01 300 500 750 GB 38 ...

Страница 46: ...Installation electric steam and gas heating 487 18 39 01 300 500 750 GB 44 2 ...