SOI/TD 2005-2 PR

/26

599 36 83-66

13

7.6 Water fill time

The opening of the solenoid valve has a pre-set overall duration, which is subdivided into the various sub-

phases of the fill:

7.6.1 Static fill time

T.S. = max 90 seconds:

This is the maximum time within which the pressure switch must switch to FULL. If

the FULL signal is not received from the pressure switch within this time, the electronic control system

interrupts the washing cycle and the appliance enters alarm condition [

1 0

].

7.6.2 Dynamic

fill

time

T.D. = T.S. x 3:

This is the maximum time allowed for the entire fill phase within which the pressure switch

signal must stabilize on FULL.

•

If the pressure switch signal does not stabilize on FULL within this period (T.S. x

3

), the electronic

control system switches off the fill solenoid (and the heating element, if switched on), and then allows

the washing cycle to proceed until it is completed. In this situation, the alarm condition [

F 0

] is not

displayed to the user, but may be accessed by the Service Engineer using a specific procedure.

•

If, during a 2600 rpm dynamic fill, the pressure switch never closes on FULL during the initial 60

seconds, the electronic control system interrupts the washing cycle and the appliance enters alarm

condition [

1 0

].

7.6.3 Power supply interruption during water fill

If the water fill phase is interrupted by opening the door or due to a power failure, the contents of the

counters are stored in memory; when the door is re-closed or when the power supply is restored, the water

fill resumes from the point at which it was interrupted; the new counter values are added to those previously

memorized.

7.7 Level stability during washing

Once the fill phase has been completed, the cycle proceeds to the washing phase. The washing phase is

carried out using cold or heated water, and the status of the pressure switch is monitored constantly to

ensure that the hydraulic system functions correctly. Water replenishment cycles may be performed if

necessary.

If the pressure switch returns to EMPTY during the washing phase, the fill solenoid is energized for a

maximum time equivalent to

T.S. x 3

(maximum allowable total fill time).

If this time is exceeded, the washing cycle is completed, but no further supplementary fills are

performed. In this situation, alarm condition [

F 0

] is stored in memory. This alarm code is not displayed to

the user, but can be accessed by the Service Engineer using a specific procedure.

7.8 Washing

system

The appliance features the classic washing system in which the mechanical washing action is

obtained by the rotation of the washing pump which, by ducting water into the hydraulic circuit, actions the

two spray arms simultaneously.

The washing pump is actioned by an asynchronous motor with a start-up capacitor (3µF– 450VL).

The washing pump rotates in a counter-clockwise direction (seen from the impeller side).

7.8.1 Control of the washing pump

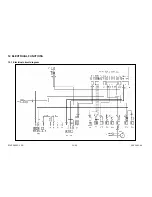

The washing pump (PL) is powered by the electronic control (connector D3-D11).

7.9 Heating

The heating element is enclosed in a protective tube, and is used to heat the washing water (but

does not switch on during the drying phase). The heating element is fitted to the outlet of the washing pump

and connected to the duct which feeds the upper spray arm.

The heating element (RR) is powered by electronic control (connector A1)

and by

the level pressure

switch (RL), which must be set to “FULL” (contact closed on 1-3).

Two safety thermostats are fitted to the heating element:

-

an automatic-reset thermostat which intervenes at 98ºC