05/21/2009 8

BI501

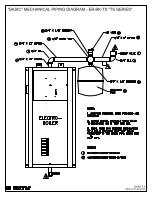

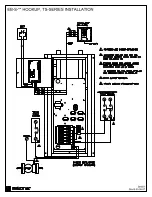

ELECTRICAL HOOKUP

Reference drawing BH501

1.

240 Volt Heating Power

– route and install the proper current carrying conductors from service

panel fuse or circuit breaker. See page 2 Specification Table and/or product nameplate for ratings.

These models contain built-in circuit breakers and meet the requirement for local disconnect

for appliances greater than 10 kW. Connection is at the circuit breaker terminals. If using

single feed method, single feed bus for GE Breakers EM5716 (two breakers) or EM5717 (three

breakers) and for Square D Breakers 5701 (two breakers) or 5702 (three breakers) should be used.

Only copper wire is allowed.

CB1 is highest priority stage.

2.

Grounding

– copper conductor is required, size per NEC code relating to the current of each feed.

3.

Circulating Pump

– the terminal block (orange wires) below the circuit breakers represents a switch

closure (10-amp maximum) to operate an external circulating pump motor.

Voltage for the pump

must come from a separate source.

The pump is controlled as a direct function of the R and W input.

If this is connected with a standby boiler, generally the assumption is series plumbing with

the single pump. In this case, the R and W function will operate the pump whether in electric

or standby mode.

If a standby boiler installation has parallel plumbing with two pumps, field wiring and

controls will be necessary to properly operate (and typically check valve isolate) the standby

boiler self-contained pump from the system pump controlled by these two terminal screws.

4.

Operating Thermostat

– two types can be used. Connection is at the control board bottom.

Standard Mechanical

– connect to “R” and “W”, bottom right. Set thermostat internal heat

anticipator to 0.2.

Electro-Stat –

(ES-24-C-RS or ES-24-SRO) 3 wire connection required.

R to R, W to W, C to common

The Electro-Stat remote sensor can be extended as required. This is a three wire cable,

cut and splice, up to 50 feet. Use only stranded wire, shielded cable is not required.

Comment:

If zone valve or zone pumps see appropriate sections.

5.

Load Management Interrupt Control

– this Electro-Boiler series has been pre-wired and designed

for an external utility load management receiver connection. The control board lower left BLU and

BLU/WHT wires represent the two contact points, extend these wires to the utility load control

device.

As shipped, this unit is only equipped for off-peak = N.C. logic. If reversed logic is required, contact

the factory for modification.

Optional – if load management is not used, simply keep the two blue wires shorted.

Optional – if the power company disconnects 240V for load control, please reference BH029

for special wiring requirements.

6.

Zone Valves or Zone Pumps

– see page 2 for zone controller options.

WARNING:

The end switches from the zone valves

must be

an

isolated contact with no voltage

present on these wires or screw terminals. This is very important to make sure there isn’t any

interference or feedback between the transformer operating the zone valve system and the transformer

within this Electro-Boiler product. Once this has been determined, all end switches are simply

paralleled with the two wires going to “R” and “W”.