18

Safety Relief Valve

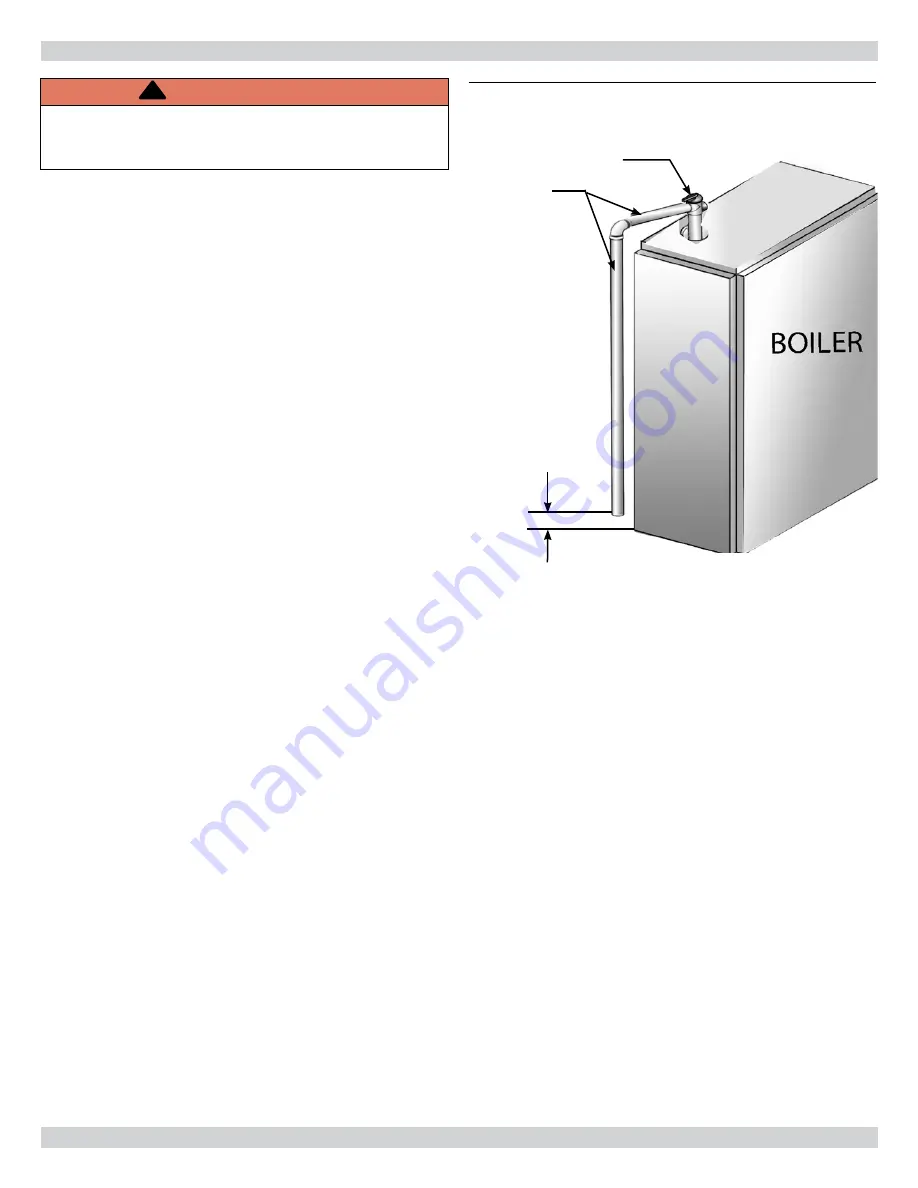

Installation of safety relief valve shall conform to ANSI/

ASME Boiler and Pressure Vessel Code, Section IV.

• Install furnished safety relief valve using 3/4” x 4½”

pipe provided with boiler. See Figure 8 .

• Install safety relief valve with spindle in vertical

position.

• Do not install shutoff valve between boiler and safety

relief valve.

• Install discharge piping from safety relief valve. See

Figure 8 .

• Use ¾” or larger pipe.

• Use pipe suitable for temperatures of 375°F (191°C) or

greater.

• Individual boiler discharge piping shall be independent

of other discharge piping.

• Size and arrange discharge piping to avoid reducing

safety relief valve relieving capacity below minimum

relief valve capacity stated on rating plate.

• Run pipe as short and straight as possible to location

protecting user from scalding and properly drain piping.

• Install union, if used, close to safety relief valve outlet.

• Install elbow(s), if used, close to safety relief valve

outlet and downstream of union (if used).

• Terminate pipe with plain end (not threaded).

Expansion Tank And Make-Up Water

Determine required system

fi

ll pressure, system design

temperature, and system water content.

• Boiler contains 2.6 gallons (U.S.). Size expansion tank

accordingly. Consult expansion tank manufacturer for

proper sizing information.

• Connect properly sized expansion tank (not furnished).

Diaphragm type expansion tank see Figure 9, Page 19 .

See Figure 10, Page 20 for conventional closed type

expansion tanks.

• For diaphragm type expansion tanks, adjust tank

air pressure to match system

fi

ll pressure. Install

furnished air vents shown for diaphragm type

expansion tank system only.

• Install make-up water connections as shown per local

codes.

• If pressure reducing valve is used, adjust to match

system

fi

ll pressure.

• Verify clean water supply is available. When water

supply is from well or pump, install sand strainer at

pump

Figure 8 - Relief Valve Boiler Piping

NEAR BOILER PIPING

RELIEF VALVE

DISCHARGE

LINE

Check local

codes for

maximum

distance

from fl oor

or allowable

safe point of

discharge

.

WARNING

Burn and scald hazard. Safety relief valve could

discharge steam or hot water during operation.

Install discharge piping per these instructions.

!

Содержание Dunkirk 4 Series

Страница 12: ...12 NEAR BOILER PIPING Figure 2 Single Zone Boiler Piping SAFETY RELIEF VALVE SEE PAGE 18 FOR REQUIREMENTS ...

Страница 15: ...15 NEAR BOILER PIPING Figure 5 Primary Secondary Piping With Circulators And Domestic Hot Water ...

Страница 31: ...31 Figure 20 Field Wiring Connections ELECTRICAL WIRING SAFETY RELIEF VALVE SEE PAGE 18 FOR REQUIREMENTS ...

Страница 33: ...33 Figure 22 Ladder Diagram for Figure 22 ELECTRICAL WIRING ...

Страница 52: ...52 Troubleshooting Chart 1 TROUBLESHOOTING ...

Страница 53: ...53 Troubleshooting Chart 2 TROUBLESHOOTING ...

Страница 63: ...NOTES ...

Страница 64: ...DUNKIRK BOILERS 2201 Dwyer Avenue Utica NY 13501 web site www ecrinternational com ...