2

2.0 Specifications

JIB burners are complete assemblies ideal for use in ovens, furnaces, kilns, or incinerators requiring simple burner

operation and easy maintenance.

1.0 Applications

Specifications

7

4.0 Start-Up & Adjustment

JIB Burners are factory-adjusted on natural gas and

tagged with the correct pressure settings. If factory

settings have been tampered with, or if the burner

will be operated on propane vapor instead of natu-

ral gas, field adjustment will be necessary. Follow

the procedure below. These general instructions

apply regardless of the type of flame monitoring

relay installed. See the appropriate data sheets for

specific information on the operation and sequenc-

ing of the particular relay installed on the burner.

CAUTION

4.1

Close the main manual gas cocks and the pilot gas

cock and turn the burner On-Off switch “Off.”

4.2

Loosen the lock nut on the gas adjusting screw (Fig-

ure 5). Using an allen wrench, turn the adjusting

screw clockwise until it seats within the burner

body. Referring to the graph in Figure 4, open the

screw the number of turns required for the desired

burner capacity.

4.3

Open the air shutter approximately 1/2" for the 210

JIB-F, and 3/4" for the 236 JIB-G.

4.4

Turn the handle of the adjustable pilot cock to the

open position, Figure 6.

4.5

Turn the burner On-Off switch “On” to start the

blower.

4.6

Once the air flow switch has proven blower opera-

tion, the flame monitoring control will be energized.

The pilot solenoid valve will open and there will be

a 15 second trial for ignition (TFI).

4.7

After the pilot ignites, adjust the pilot gas cock by re-

moving the top screw, Figure 6. Turn the adjusting

screw clockwise to reduce gas flow, and counter-

clockwise to increase gas flow. When the desired

setting is reached, replace the top screw.

Pilot gas should be adjusted to the minimum flow

which holds the flame monitoring device and

posi-

tively

ignites the burner. If the pilot gas input is too

low, nuisance shutdowns will occur; if the input is

too rich, aldehydes form.

Eclipse Controls flame monitoring relays have a

front panel pilot test button that will hold the burner

on pilot, giving you as much time as you need to

adjust the pilot. See I-610 Information Guide for de-

tails on this feature.

4.8

The flame monitor will prove pilot operation and

energize both main gas solenoid valves.

4.9

Open the main manual gas cocks. After the main

flame is lit, adjust the air shutter if necessary to

achieve the desired flame characteristics.

4.10

When the burner is fully adjusted, lock the air shut-

ter and gas adjusting screw in place.

4.11

If necessary, re-adjust the pilot setting to compen-

sate for changes in the air shutter opening.

4.12

The burner can now be operated without further

adjustment, using only the on-off switch.

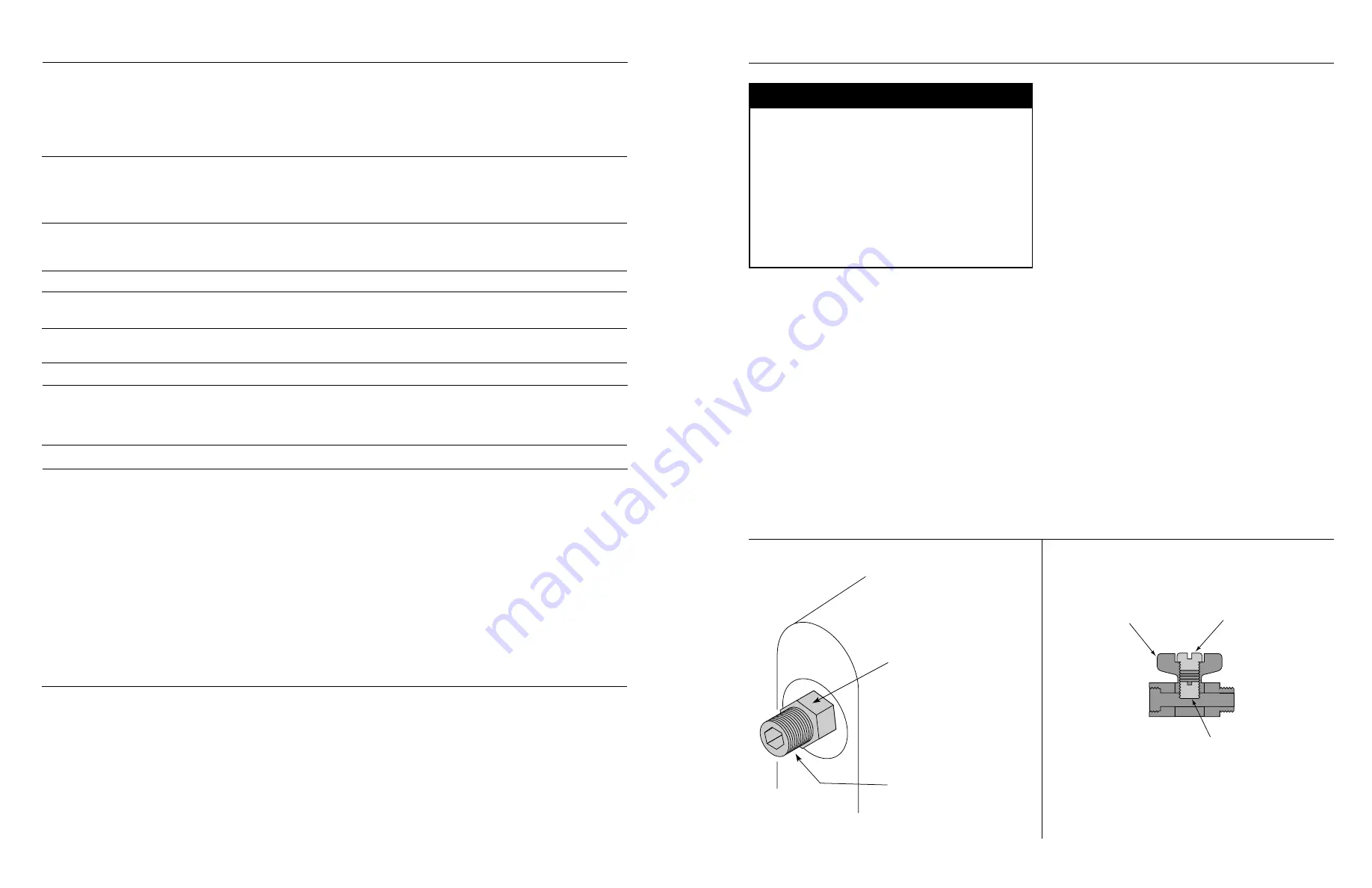

Figure 5—Main Gas Adjusting Screw

Figure 6—Pilot Cock

Top Screw

Handle—

Shown in

Open Position

Adjusting Screw—

Clockwise for less pilot gas;

Counter-Clockwise for more pilot gas.

Locknut—Loosen before

adjustments; tighten

afterwards.

Adjusting Screw—Clockwise (in)

for less gas;

counterclockwise (out)

for more gas.

See Figure 1 for adjusting screw location.

Inputs

Burner

Btu/hr.

kW

Natural gas or propane vapor

210 JIB-F

750,000

219.8

236 JIB-G

1,000,000

293.0

Gas Inlet Pressures

Burner

Minimum

Maximum

At valve train inlet

210 JIB-F

5.0" w.c.

12.5 mbar

14.0" w.c.

34.8 mbar

236 JIB-G

8.3" w.c.

20.7 mbar

14.0" w.c.

34.8 mbar

Electrical Supply

120 VAC, 1 cycle, 60 hz.

Motor Type

210 JIB-F:

1/25 hp, 1550 rpm, open, with built-in overload protection.

236 JIB-G:

1/6 hp, 3600 rpm, TEFC, with built-in overload protection.

Firing Chamber Limits

Draft required: 0.05" w.c. (0.1 mbar) to 1.5" w.c. (3.7 mbar).

JIB burners will not operate against any backpressure.

Ambient Temperature Limits

-40

°

to +104

°

F (-40

°

to +40

°

C)

Materials

Burner Body:

Cast iron

Blower Housing:

Cast iron.

Impeller:

Steel.

Flame tube:

Cast iron.

Net Weight

72.5 pounds

32.9 kilograms

Models

Burner

Assembly

Flame Monitor

Sensor

Sensor #

210 JIB-F

109789-00

None

1

None

---

210 JIB-F

109789-33

Eclipse 5605-33

Flame rod

13093-3

2

210 JIB-F

109789-01

Honeywell RA-890F

Flame rod

13093-3

2

210 JIB-F

109789-04

PCI 7256 BE

Flame rod

13093-3

2

210 JIB-F

109789-32

Eclipse 5605-32

UV scanner

10939

210 JIB-F

109789-02

Honeywell RA-890G

UV scanner

16281

210 JIB-F

109789-05

PCI 7256 BE

UV scanner

17265

236 JIB-G

109749-00

None

1

None

---

236 JIB-G

109749-33

Eclipse 5605-33

Flame rod

13093-3

2

236 JIB-G

109749-01

Honeywell RA-890F

Flame rod

13093-3

2

236 JIB-G

109749-04

PCI 7256 BE

Flame rod

13093-3

2

236 JIB-G

109749-32

Eclipse 5605-32

UV scanner

10939

236 JIB-G

109749-02

Honeywell RA-890G

UV scanner

16281

236 JIB-G

109749-05

PCI 7256 BE

UV Scanner 17265

1

Burners ordered less relay include an ignition plug, ignition transformer, and ignition cable. The customer must

supply a suitable flame monitoring relay, base, and flame sensor meeting local and/or insurance requirements. To

mount a UV scanner on the burner, order scanner adaptor #19748.

2

Flame rod #13093-3 is furnished 3-1/4" long; it must be cut to 2-1/2" long to be used in the burner.

Flame monitoring equipment supplied with these burners by Eclipse may or may not meet local safety and/

or insurance requirements. The owner/user and/or his insurance underwriter must assume responsibility for

the acceptance, use, and proper maintenance of flame supervision, limit controls, and other safety devices.