9

Section III – Test Procedure

A. Test

1. Utilize your present control system to test the servo

valve as follows:

CAUTION

Check polarity of 0-500 milliammeter with system

polarity prior to installation to prevent meter damage.

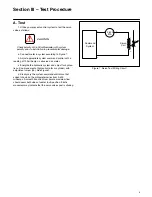

a. Connect meter in system according to Figure 7.

b. Adjust appropriate system command control until a

reading of 190 milliamps is observed on meter.

c. Energize the hydraulic system and adjust for hydrau-

lic null (no movement of hydraulic motor or cylinder) with

adjustment screw (25). See Figure 1.

d. Slowly vary the system command controls so that

current shown on the milliameter varies from 0-400

milliamps. A smooth transition from zero to maximum flow

should occur both sides of center (null) position. Erratic

movement may indicate that the servo valve spool is sticking.

Figure 7. Servo Test Wiring Circuit

Command

System

Servo

Coil

0-500

MA

–

–

+

–

+

+