7

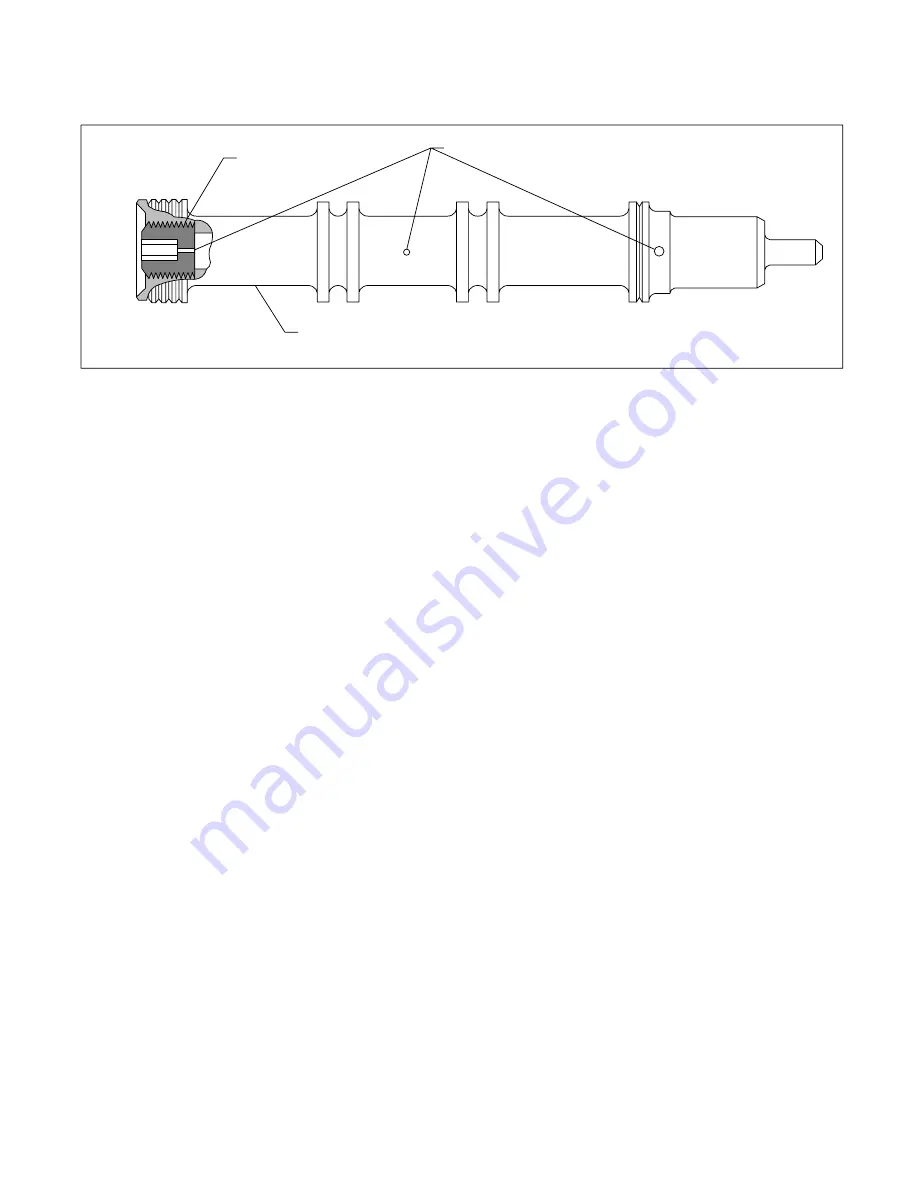

Figure 5. Spool Subassembly

Orifice Plug

See Note:

Holes must be clean

Note: Grip here if orifice plug must be

removed to clean inside of spool.

f. Place a 0.010 shim between the flapper armature (13)

and the nozzle (20) while tightening the two holding screws

and lockwashers (12). See Figure 3.

NOTE

The flapper armature must be square with the

nozzle when the operation is completed and have a

0.010 clearance. A change in the setting of the

adjustment screw (25) may be required during this

procedure to keep the flapper armature square with

the nozzle.

3. Install O-Ring parts (29) thru (27) into valve body

(37).

4. Insert spool subassembly (33) into body (37). The

small end of the spool must extend from the valve

approximately one inch. Assemble the pilot stage (adapter

subassembly (26)) over the spool for alignment purposes.

Guide coil wires thru body hole and align the coil connector

with body hole while installing. See Figure 4. Tighten the

adapter holding screws (10) and washers (11) alternately

until the pilot stage is flush against the valve.

5. Check spool to see that it doesn’t bind in the adapter

(26) then torque the screws to 16-18 lb. in. Recheck for

binding.

6. Assemble the feedback spring (14) to the flapper

armature by twisting the spring over the extrusion until the

spring is tight against the flapper armature. Use a twisting

motion only, lateral force against the flapper armature may

bend it. See Figure 4.

7. Assemble parts (34) and (32) thru (30).

8. Turn adjusting screw (25) until light can just be seen

between the flapper and orifice, point ”A”, Figure 4. This is a

preliminary null adjustment.

9. Assemble clamp (9) and screw (8) over the wire.

Route the wire ends thru the hole to the outside of the valve.

See Figure 4.

NOTE

The name plate, gasket, and screws, parts (7) thru

(5), should not be installed at this time since a final

null adjustment must be made before normal

operation can begin.

10. Install parts (4) thru (1). Torque screws (2) to

16-18 lb. in.