6

2. Check the 0.060 hole in the nozzle (20).

3. Check frame (22) for cracks or distortion.

4. Check the feedback spring (14) for distortion.

5. Make a continuity check of the coil and seal

subassembly (16). Resistance values should range from 18

to 22 ohms. This test is superficial but a more rigorous test

requires special equipment.

6. Check the adapter (26) and spool mating surfaces.

Insert the spool into the adapter and rotate the spool. The

spool must not bind in any position.

G. Assembly

Replace the gaskets and O-Rings with those supplied in the

gasket kit. Apply a light film of clean system fluid to the parts

prior to installing them. This will make assembly easier and

provide initial lubrication. Special procedures are included in

the following steps:

1. Assemble parts (37) thru (35). See Figure 1.

2. Assemble the pilot stage portion of the valve as

follows:

a. Assemble parts (26), (22) , (21) and (20).

b. Install adjusting screw (25) thru the adapter (26),

attach standard nut (24) and washer (23) and turn the nut on

until it bottoms against the shoulder of the adjusting screw.

See Figures 2 and 3.

c. Turn the adjusting screw (25) thru the hole on the

frame (22) far enough to attach the other washer (19) and

lock nut (18).

d. Turn one of the nuts until it contacts the frame,

then tighten the other nut. See Figure 2.

NOTE

After tightening the nuts (18) and (24) against their

respective washers, the adjusting screw (25) should

turn free and have no end play between the screw

and the frame (22).

e. Assemble parts (17) thru (15). See Figure 1.

CAUTION

Be careful when installing flapper armature (13). The

securing screws (12) extend thru the frame (22) and

could break the insultation on the coil. See Figure 3.

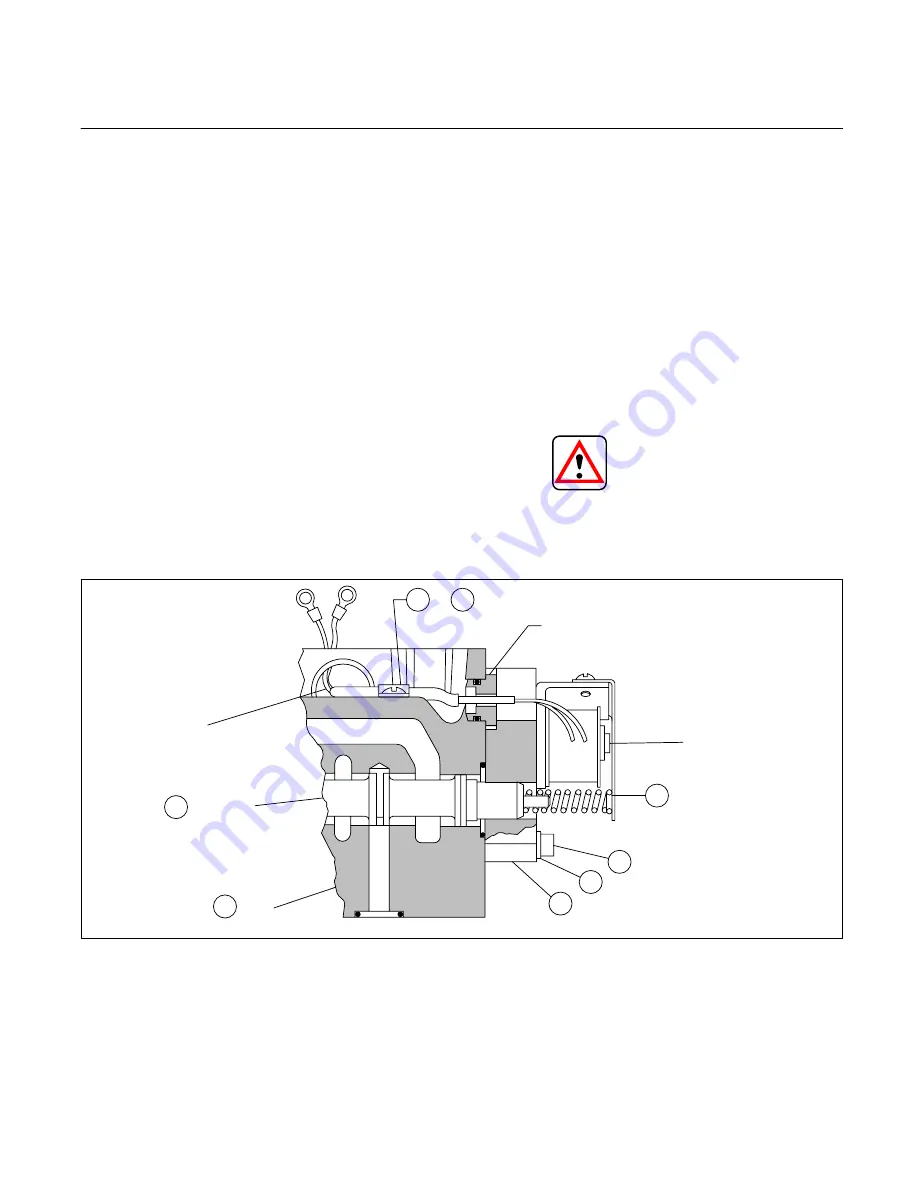

Figure 4. Sectional View

Wires

8

9

14

10

11

26

37

33 Spool S/A

Body

&

Clamp and Screw

Note: Push coil connector out of

body at same time pilot

stage is being removed.

Feedback Spring

Screw

Washer

Adapter S/A

”A”