EATON

PVM Piston Pump Service Manual E-PUIO-II001-E4 December 2017

3

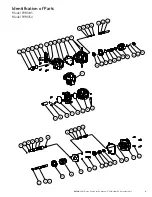

Basic Pump

Figure 1 shows the basic construction of the PVM series

piston pump. Major parts include the 1. Shaft 2. Housing,

3. Swash plate,4. Rotating group, 5. Valve plate, 6. Control

sleeve, 7. Control rod, 8. End Cover, 9. Control 10. Flange

Figure 1

Pump Operation

In axial piston pumps, the pistons reciprocate parallel to the

axis of rotation of the cylinder barrel. The simplest type of

axial piston pump is the swash plate in-line design. The cyl-

inder barrel in this pump is turned by the drive shaft. Pistons

fitted to bores in the cylinder barrel are connected through

piston shoes and a shoe plate, so that the shoes bear against

an angled swash plate.

As the barrel turns, the piston shoes follow the swash plate,

causing the pistons to reciprocate. The ports are arranged in

the valve plate so that the pistons pass the inlet as they are

pulled out and pass the outlet as they are forced back in. The

displacement of axial piston pumps is determined by the size

and number of pistons, as well as the stroke length which

is determined by the angle of the swash plate. In variable

displacement Models of the in-line pump, the swash plate is

installed in a saddle Bearing. “Pivoting” the swash plate in

saddle bearings changes the swash plate angle to increase or

decrease the piston stroke.

Pump Controls Types

Three common pump control types are available. One type is

the standard “A” compensator control that limits pump outlet

pressure to a desired level. The other type is the “B+C”

pressure limited/load sensing control. Now available is the

“IC” (Industrial Control) which can be used as a load sensing

compensator, remote compensator control and electrohydrau-

lic control. These limit pump outlet pressure and also regulate

pump displacement to match load requirements. A cold start

valve option is also available.

Pump Description