To order parts and supplies: 800.343.9353 >> eastwood.com

13

SET-UP THE MIG 90 FOR FLUX CORE WELDING

The Eastwood MIG 90 comes factory set-up to weld with Solid Wire and Shielding Gas.

Flux Core does not require shielding gas.

Three changes to the Set-Up need to be made to MIG Weld with Flux Core wire:

- Reverse polarity from DCEP to DCEN.

- Install Flux Core wire.

- Position Drive Roller to accept Flux Core wire.

CHANGING THE POLARITY TO DCEN FOR WELDING WITH FLUX CORE WIRE

To use a Flux Cored wire, the Polarity of the short Integral Ground Connection Lead

[g]

attached to the Front Panel must be reversed

(Fig 12)

.

• Disconnect the Short, Integral Ground Connection Lead [g] from the Positive (+)

Connection Receptacle

[f]

by rotating the Rubber Insulator 1/2 turn Counter-

Clockwise and pulling outward.

• Align the key of the brass ferrule with the notch of the receptacle at the 12:00

position, then insert the Lead [g] onto the Negative ( - ) Connection Receptacle

[h]

, seat fully and rotate 1/2 turn Clockwise to lock

(FIG 12)

.

• Insert and lock the Ground Clamp Cable into the (+) Positive Connection

Receptacle

[f]

(FIG 12)

.

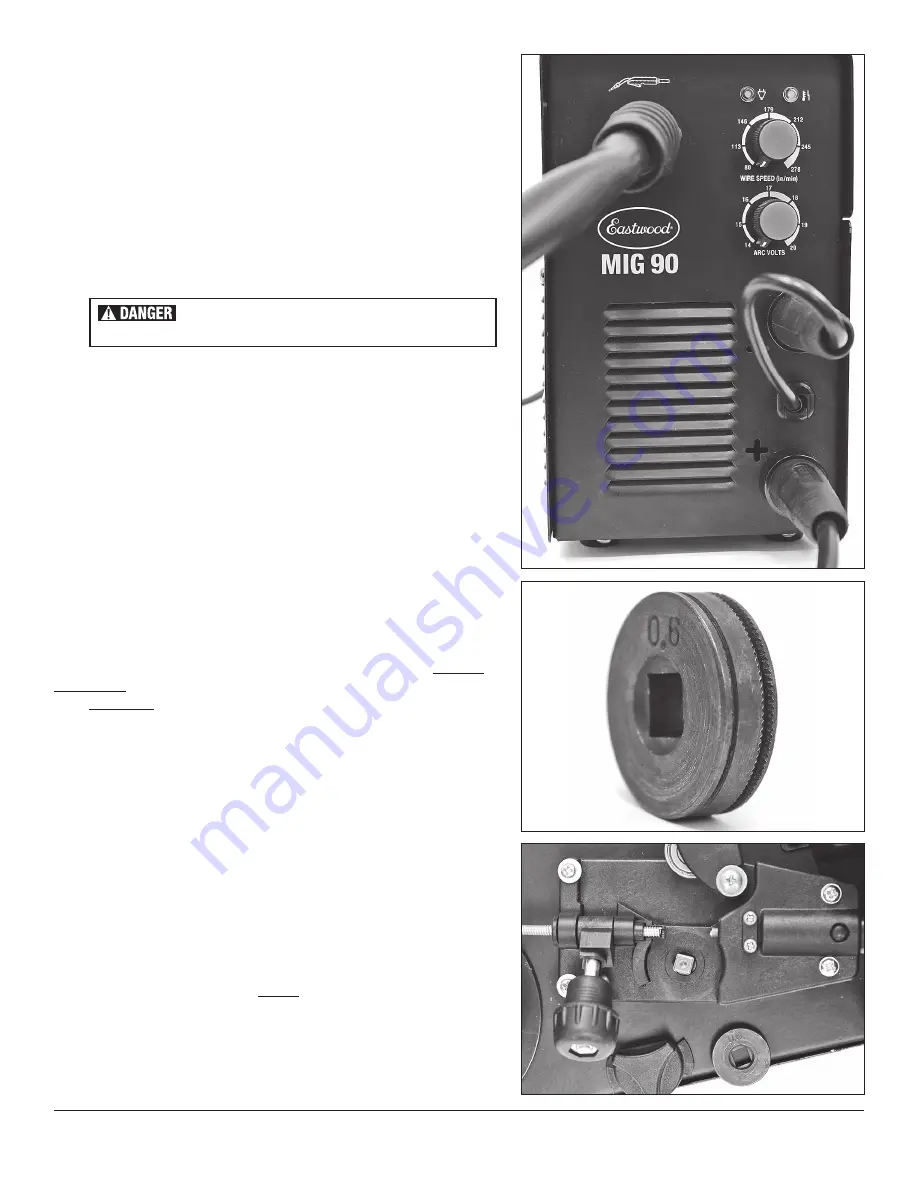

POSITIONING DRIVE ROLLER FOR WIRE SIZE

The Eastwood MIG 90 Wire Drive Roller has twin grooves to accommodate both

0.023” [0.6mm] and 0.030”/ [0.8mm] wire.

The MIG 90 Drive Roller is factory set and up ready to use 0.023” (0.6mm) solid wire.

IMPORTANT NOTE:

In this position, the narrower, 0.023”/ [0.6mm grove is outboard,

under the wire while the 0.6 marking for the narrower 0.023” [0.6mm] wire is visible

on the outward face of the Drive Roller.

To Clarify; The stamped marking on the side of the drive roller indicates the size of the

groove on the opposite side of the roller

(FIG 13)

.

The groove furthest from the drive motor is the groove that will be used. If setting up

to use larger 0.030” [0.8mm] wire, the “0.8” stamping should be facing the user

when installing it.

Reverse the drive roller position according to the following procedure:

• Open the top door of the Welder to access the drive motor compartment.

• Rotate the Pressure Adjuster out of the way then pivot the Tension Arm away

from the Drive Roller

(FIG 14)

.

• Loosen and remove the Drive Roller Retaining Knob

(FIG 14)

.

• Remove the Drive Roller and view the wire sizes stamped on each side of

the Roller.

• Install the Drive Roller on the square drive, in the proper orientation with the

chosen wire size stamping facing outward

(FIG 13)

.

• Reinstall the Drive Roller Retaining Knob on the shaft.

• Replace the Tension Arm and re-latch the Pressure Adjuster.

ELECTRIC SHOCK CAN CAUSE INJURY OR DEATH!

Disconnect Welder from power supply before beginning.

FIG. 12

FIG. 12

FIG. 13

FIG. 13

FIG. 14

FIG. 14