4810 Clover Road • Greensboro, NC 27450 • 1-800-336-2776 • www.eagleequip.com • © Eagle Equipment 2018.01 • page 14

2. ASSIST ARM APPLICATION CONT.

2.1 ASSIST ARM COMPONENTS

Each components of assist arm device are introduced as follows

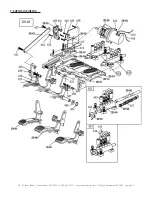

Figure 16 and 19:

A. Swing arm

B. Small assist arm

C. Roller C

D. Raise-fall roller handle

F. Locking switch for assist arm

G. Roller G

H. Tire pressing roller

S. Control switch

T. Tire pressing head

The function of the assist arm’s control handle is as follows:

Lift the roller handle (D, Figure 16) is for lifting and lowering roller C (G, Figure

16) so as to adjust tire demount/mount vertical height. Operate handle (D, Figure

16) up, then roller C (G, Figure 16) goes up, Operate handle (D, Figure 16) down

then roller C (G, Figure 16) goes down.

2.2 OPERATION

It is difficult to demount and mount big low profile tire. If operation is proper,

it is very easy to use assist arm device to demount and mount tire from rim. The

assist arm device may also be used when demounting and mounting normal tire

with resistance.

A. Clamp rim

Firstly, press both side tire loose as per operation instruction in user’s manual, fixing the tire on the tire

installation base.

B. Demount tire

1. Press tire with right pressing roller C/G to a position 3cm lower than rim edge, lubricate tire

bead, rotate turntable, lift roller C (G, Figure 16).

2. Move demount/mount head close to edge of rim, keep a 2-3mm gap between demount/mount

head and rim plane, lock vertical arm, adjust screw bolt in column to position swing arm.

3. Nearby demount/mount head, insert lift lever N into tire, use lift lever to lift bead upon knob

of demount / mount head. Manually rotate roller C to inner side pull handle D down, make

roller C to press rim keep 3-5mm gap between demount/mount head and rim, make sure

demount/mount head not damage rim, rotate tire installation base, demount tire upper bead

(Figure 18)

4. Push handle D up lift roller C (G) press switch F loosen right pressing arm, lift tire up, insert

lifting level into bottom tire bead nearby demount/mount head, lift bead upon knob of

demount/mount head and rotate the turntable to demount down tire bead.

During the above operation, the user can use the left assist arm to help the user. For

example: pressing the wheel hub, flattening or lifting up the tire from the side with the tire

pressing (Figure 19 and 20).

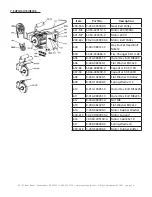

Figure 23

Figure 22