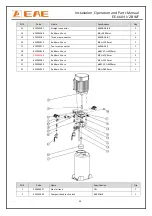

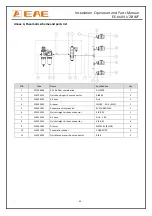

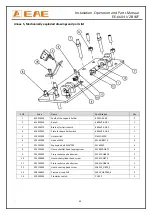

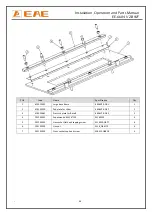

Installation, Operation and Parts Manual

EE-6604 V2.BWF

-

22

Annex

1,

Floor

Plan

Requirements:

1.425#

concrete

base

with

strength

more

than

3000psi,

tolerance

of

flatness

less

than

5mm

and

minimum

thickness

of

200mm.Newly

built

concrete

ground

must

be

older

than

20days.

2.

Concrete

thickness

of

the

base

shall

be

more

than

150mm

and

remove

the

peel

‐

offs

in

the

bit

3.

Flatness

of

the

two

base

shall

within

the

tolerance

of

5mm.

4.

Embedded

L40

angle

iron

around

the

pit

for

edging.

5.

In

case

drain

pipes

are

not

applicable,

it

is

necessary

to

reserve

a

plash.

1.Surfacing

Mouting

Содержание EE-6604V2 .BWF

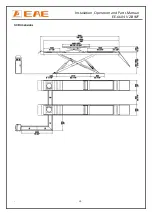

Страница 10: ...Installation Operation and Parts Manual EE 6604 V2 BWF 10 3 3 Dimensions...

Страница 23: ...Installation Operation and Parts Manual EE 6604 V2 BWF 23 2 Recessed Mounting...

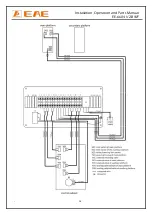

Страница 24: ...Installation Operation and Parts Manual EE 6604 V2 BWF 24 Annex 2 Electrical schemes and parts list...

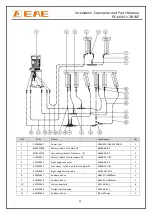

Страница 25: ...Installation Operation and Parts Manual EE 6604 V2 BWF 25...

Страница 26: ...Installation Operation and Parts Manual EE 6604 V2 BWF 26...