Installation, Operation and Parts Manual

EE-6604 V2.BWF

-

14

4.2.3

Do

not

place

any

vehicle

on

the

lift

in

the

case

of

trial

running.

4.3

General

Installation

Steps

Step

1:

Choose

installation

site.

Use

a

fork

lift

to

place

the

two

lifting

platforms

into

installation

site

as

required.

See

Annex

1

for

space

requirements

on

the

installation

site.

Step

2:

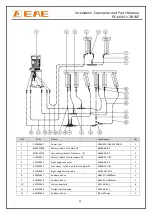

Connect

hydraulic

oil

hoses.

Connect

the

oil

hoses

to

the

power

unit

as

per

the

diagram

for

oil

hose

connection.

Annex

3.

Attention:

Connect

as

per

the

marks

on

the

hoses

and

do

not

contaminate

the

hydraulic

components

during

the

connection.

Step

3:

Connect

pneumatic

hoses.

Connect

the

pneumatic

release

system

by

the

diagram

of

air

hose

connection

in

Annex

4.

Attention:

Connect

as

per

the

marks

on

the

hoses

and

do

not

contaminate

the

pneumatic

components

during

the

connection.

Step

4:

Connect

electrical

wires.

Refer

to

the

electrical

connection

scheme.

Connect

the

power

supply

and

the

quick

connecters

for

limit

switch.

(For

three

phase

power

supply

,if

the

lift

doesn't

raise

and

the

motor

may

turn

in

the

wrong

direction,

in

such

event,

interchange

wires

U,

V

in

the

control

cabinet)

.

Step

5:

Fill

with

hydraulic

oil.

ONLY

CLEAN

AND

FRESH

OIL

ONLY

.Lift

must

be

fully

lowered

before

changing

or

adding

hydraulic

oil.

Normally

it

needs

22

liters

of

hydraulic

oil.

Initially,

fill

the

tank

full

with

about

18L

of

hydraulic

oil

.

Run

the

lift

for

several

cycles

and

add

another

4L

into

the

tank.

The

level

of

oil

shall

reach

the

tippets

volume

mark

of

the

tank.

Run

the

lift

for

several

cycles

and

add

more

oil

until

the

lifting

platform

can

reach

its

maximum

height.

Note

:

As

running

speed

of

the

lift

is

mainly

decided

by

the

viscosity

of

the

hydraulic

oil,

we

suggest

using

NO.46

hydraulic

oil

when

average

temperature

of

the

location

is

above

18

degree

Celsius

and

using

NO.32

hydraulic

oil

when

temperature

is

below

18

degree

Celsius.

Change

the

oil

6

months

after

initial

use

and

change

once

per

year

thereafter.

Step

6:

Levelling

Check

the

connection

of

the

hydraulic

and

electrical

system

before

levelling

operation

Review

operation

instructions

and

get

familiar

with

lift

controls

by

running

the

lift

through

a

few

cycles

before

levelling

opearion.

Attention:

Level

the

platforms

before

connecting

max

height

limit

switch

because

if

not,

platforms

may

not

rise

to

the

highest

position.

The

operator

needs

to

know

clear

which

levelling

valve

controls

which

platform.

This

could

be

judged

by

the

way

that

the

oil

hose

was

connected

or

by

trial

raising

or

lowering.

Check

the

connection

of

the

hydraulic

and

electrical

system

before

levelling

operation

Review

operation

instructions

and

get

familiar

with

lift

controls

by

running

the

lift

through

a

few

cycles

before

leveling

opearion.

Levelling

the

main

lift.

1)Turn

on

the

main

power

switch

and

turn

the

selection

switch

SA2

to

the

main

lift

and

SA1

to

“Levelling”

status.

Turn

the

two

handles

of

levelling

valve

to

the

following

status.

Содержание EE-6604V2 .BWF

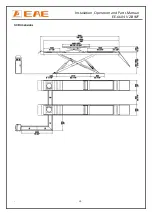

Страница 10: ...Installation Operation and Parts Manual EE 6604 V2 BWF 10 3 3 Dimensions...

Страница 23: ...Installation Operation and Parts Manual EE 6604 V2 BWF 23 2 Recessed Mounting...

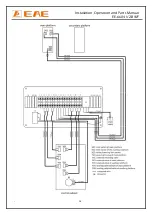

Страница 24: ...Installation Operation and Parts Manual EE 6604 V2 BWF 24 Annex 2 Electrical schemes and parts list...

Страница 25: ...Installation Operation and Parts Manual EE 6604 V2 BWF 25...

Страница 26: ...Installation Operation and Parts Manual EE 6604 V2 BWF 26...