M500 USER MANUAL AND PROGRAMMER SDK

Page 27

10.

M

AINTENANCE

10.1

C

ALIBRATION

C

ARD

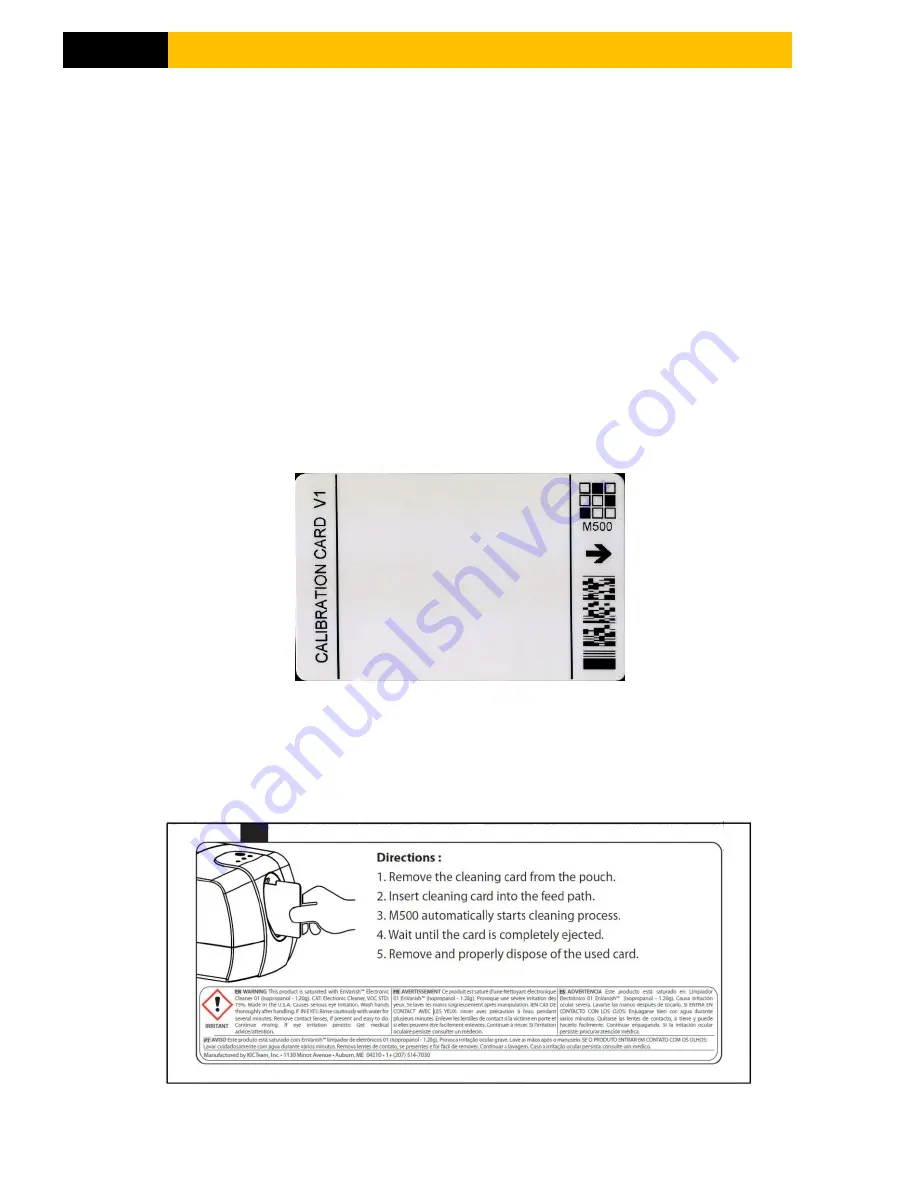

The main Purpose of the White Calibration Card is to perform a white color balance calibration. This

calibration occurs when the Calibration Card is inserted into the M500 with the ARROW FACING IN

towards the M500. (See the Calibration Card illustration below). When this Calibration process is

performed, an EV_WHITE_CAL event will occur, which will cause certain settings to be calculated and

stored within the M500. During this process, the data displayed through the application software will be

the previous calibration settings. The new settings will not be displayed until the next scan. These

settings are used for color balance calculations within the M500 during normal scanning operation.

The secondary purpose of the White Calibration Card feedback in the determination of whether or not

dust or debris may have accumulated on the M500’s mirrors. The Verification Process occurs when the

Calibration Card is inserted into the M500 with the ARROW FACING OUTWARD. When this is performed,

an EV_WHITE_CALV will occur. At this point, the application software should display RGB images to the

user to facilitate the determination of whether or not there is dust or debris on the mirrors. Note. The

Verification process does NOT re-calibrate the M500.

Calibiration Card

The cleaning card is designed to clean the internal rollers and the Magnetic Read Head inside the M500.

The need for cleaning varies, but is primarily dependent on the usage or the number of card scans. The

general guideline is for cleaning once a month for high usage and once every three months for low

usage environments. This process is very simple to perform as it is an automatic process once the

cleaning card is inserted into the M500.