Page 8

3101B MANUAL

02/08

MODEL 3101B

DELAY EGRESS SYSTEM

INSTALLATION INSTRUCTIONS

705 Emmett Street Bristol, CT 06010

1-877-DynaLock www.dynalock.com

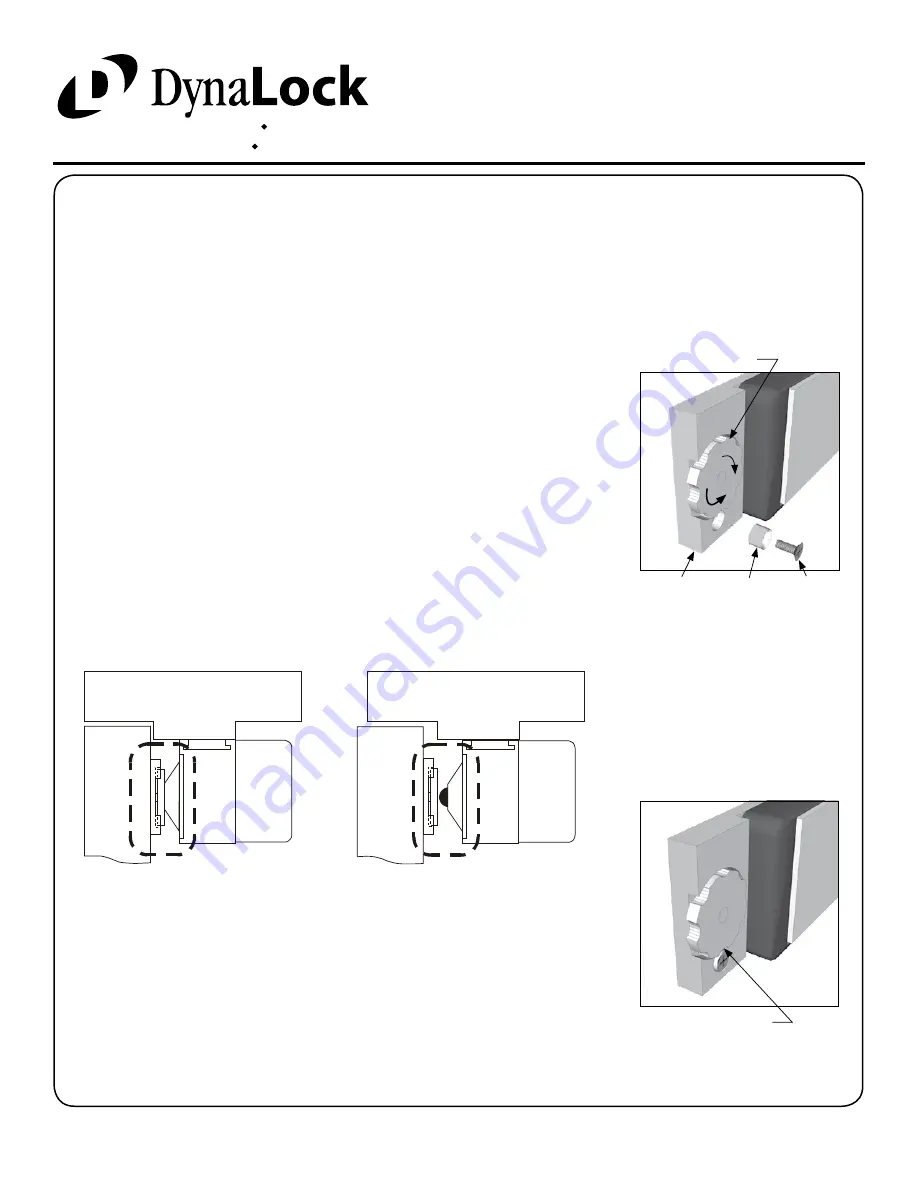

EGRESS SENSOR ADJUSTMENT

WHEEL STOP INSTALLED

(LOCKS ADJUSTMENT)

SEE PAGE 10 FOR LOCATION OF ELECTRONIC PARTS MENTIONED IN THIS SECTION

The sensor and armature assembly are designed for use on a door with existing mechanical latching hardware. If used

on a door without a latch, false alarms are possible. In these cases, we suggest using an external trigger such as our

6451 Exit Sensor Bar - connect using terminals 11&12 and disable this internal sensor (see pages 10&11).

With the door closed and latched apply input power to terminals 1 & 2. Slide

selector switch (DS1) #1 to the ON position to activate the Set-Up mode.

Rotate the on-board keyswitch counter-clockwise. The 3101B should now

be unlocked (LED1-OFF).

Open the door. Temporarily remove the Adjustment Wheel Stop from the

Armature Mounting Plate and close the door. Set aside for re-installation

later.

With the door closed observe the bi-color LED (LED1) on the circuit board. It

should be lit red. If it is not lit, rotate the adjustment wheel counter-clockwise

as necessary to ensure that it will contact and fully depress the ball plunger

on the lock. Rattle the door to ensure the LED remains lit.

With the door closed and LED1 lit red, unlatch and slowly open the door. The

LED will shut off as soon as the door opens far enough for the ball plunger

to fully project.

With adjustment completed, re-install the adjustment wheel stop to lock-in

the adjustment. Close the door, slide selector switch (DS1) #1 back to the

OFF position and return the on-board keyswitch to the center position to re-

lock the 3101-B.

Unlatch and push on the door until delay egress triggers (1-3 seconds). The

audible will sound and LED1 will flash red. After 15 seconds the lock will

release. Turn the on-board keyswitch clockwise to reset the lock. If delayed

egress triggers too soon, or fails to trigger, re-adjust the sensor adjustment

wheel for desired sensitivity.

WHEEL

STOP

MOUNTING

SCREW

WHEEL

STOP

EGRESS SENSOR

ADJUSTMENT WHEEL

ARMATURE

MOUNTING

PLATE

1.

2.

3.

4.

5.

6.

DOOR CLOSED AND LATCHED

DOOR UNLATCHED & MOVED