UART Error Codes:

1 - Not Supported Command or Back Door is not enabled.

2 - Wrong # of Arguments.

3 - Address is Out of Range (MR or MW commands).

4 - Wrong # of the characters in the Argument.

5 - Attempt to Alter Write Protected Area in the EEPROM.

6 - Proper Command or Argument is not found.

7 - Wrong value of the Argument.

8 - Reserved.

9 - Manufacture specific info EE KEY (wrong key or key is disabled).

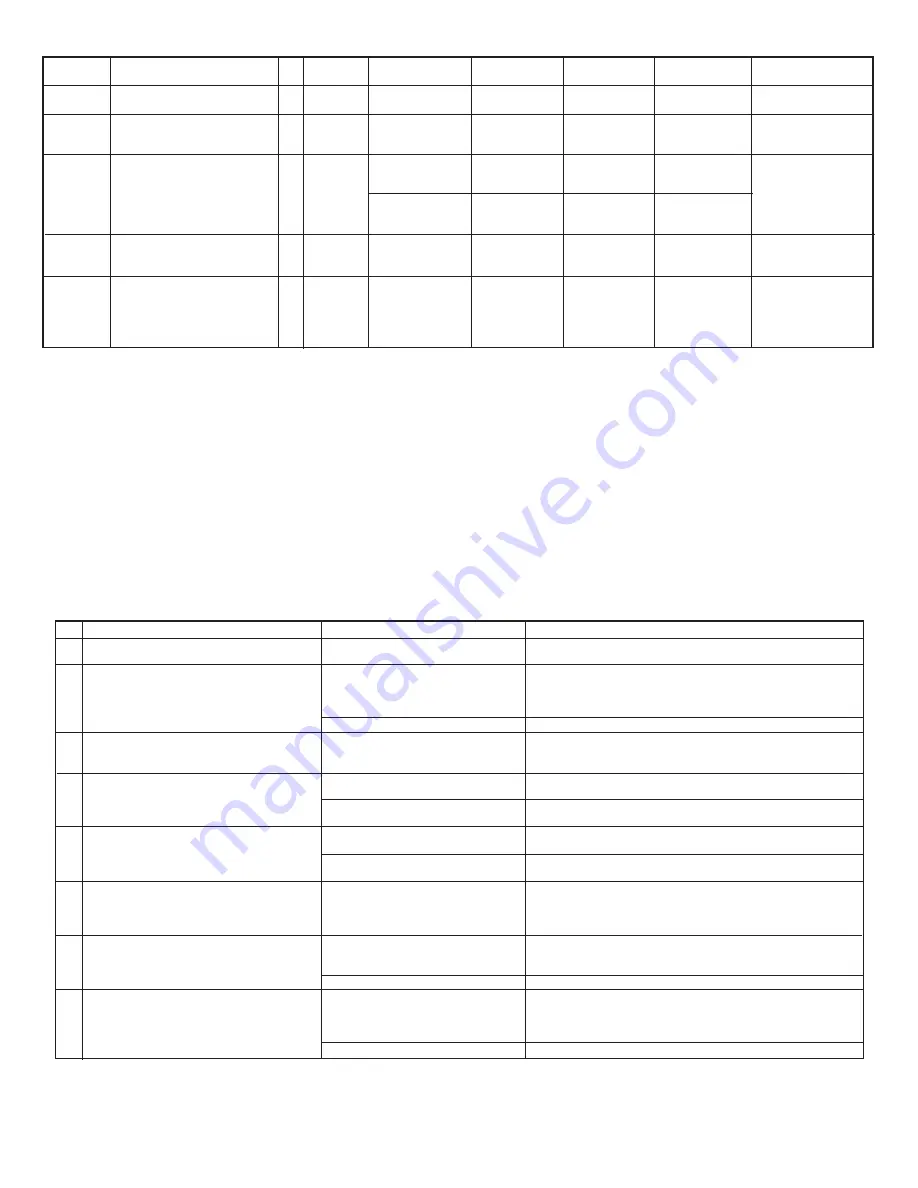

9. TROUBLESHOOTING

9.1 Common Conditions

Your GFM2 Digital Mass Flow Meter was thoroughly checked at numerous quality

control points during and after manufacturing and assembly operations. It was

calibrated according to your desired flow and pressure conditions for a given gas

or a mixture of gases.

It was carefully packed to prevent damage during shipment. Should you feel that

the instrument is not functioning properly, please check for the following common

conditions first:

Are all cables connected correctly? Are there any leaks in the installation? Is the

power supply correctly selected according to requirements? When several meters

are used a power supply with appropriate current rating should be selected.

Were the connector pinouts matched properly? When interchanging with other

manufacturers' equipment, cables and connectors must be carefully wired for

correct pin configurations. Is the pressure differential across the instrument

sufficient?

Command

Name

Maintenance

Timer

Full Scale

LCD Back

Light

Read

EEPROM

Memory

Write

EEPROM

Memory

Description

Hours since last time unit was

calibrated.

Returns the full scale rated flow in

L/min. (Note: This term is not

multiplied by the current K factor)

LCD Back Light control

(0-100.0%)

0 - off

100 - Maximum Intensity

Reads the value in the

specified memory location.

Writes the specified value to the

specified memory location. Use

Carefully, can cause unit to

malfunction. (Note: Some

addresses are write protected!)

No.

11

12

13

14

15

Command

C

E

B

MR

MW

Argument 1

R (read timer)

C (set timer to zero)

0 to 100%

No Argument

<current settings>

0000 to 999

(Table Index)

0000 to 999

(Table Index)

Argument 2

Value

Argument 3

Argument 4

Response

<Value> (in Hours)

CC

<Value> (in L/min)

B:<Counts>

where:

Counts (0 – 4095)

B:<Value>

where:

Value (0 – 100.0)

<value>

MW,XXX,<Value>

where:

XXX=Table Index

No.

1

2

3

4

5

6

7

8

Indication

No zero reading after 15 min. warm up time and

no flow condition.

Status LED indicator and LCD display remains

blank when unit is powered up. No response

when flow is introduced from analog outputs 0 to

5 VDC or 4 to 20 mA.

LCD display reading and/or analog output 0 to 5

VDC signal fluctuate in wide range during flow

measurement.

LCD display reading does correspond to the

correct flow range, but 0-5 Vdc output signal

does not change (always the same reading or

around zero).

LCD display reading and 0 to 5 Vdc output

voltage do correspond to the correct flow range,

but 4 to 20 mA output signal does not change

(always the same or reading around 4.0 mA).

Calibration is off (more than ±1.0% FS).

LCD display reading is above maximum flow

range and output volt age 0 to 5 VDC signal is

more than 5.0 VDC when gas flows through the

GFM2.

Gas flows through the GFM2, but LCD display

reading and the output voltage 0 to 5 Vdc signal

do not respond to flow.

Likely Reason

Embedded temperature has been

changed.

Power supply is bad or polarity is

reversed.

PC board is defective.

Output 0-5 Vdc signal (pins 2–1 of the D-

connector) is shorted on the GND or

overloaded.

Output 0 to 5 VDC schematic is burned

out or damaged.

Analog flow output scale and offset

variable are corrupted.

External loop is open or load resistance

more than 500 Ω.

Output 4 to 20 mA schematic is burned

out or damaged.

GFM2 has initial zero shift.

Sensor under swamping conditions (flow

is more than 10% above maximum flow

rate for particular GFM2).

PC board is defective.

The gas flow is too low for particular

model of GFM2.

GFM2 models: RFE is not connected

properly to the inlet fitting.

Sensor or PC board is defective.

Solution

Perform Auto Zero Procedure (see section 5.3.6 “Zero

Calibration”).

Measure voltage on pins 7 and 5 of the 15 pin D-connector. If

voltage is out of specified range, then replace power supply with a

new one. If polarity is reversed (reading is negative) make correct

connection.

Return GFM2 to factory for repair.

Check external connections to pin 2 – 1, of the D-connector. Make

sure the load resistance is more than 1000 Ω.

Return GFM2 to factory for repair.

Restore original EEPROM scale and offset variable or perform

analog output recalibration (see section 7.3).

Check external connections to pins 2 and 15 of the D-connector.

Make sure the loop resistance is less than 500 Ω.

Return GFM2 to factory for repair.

Shut off the flow of gas into the GFM2 (ensure gas source is

disconnected and no seepage or leak occurs into the meter). Wait

for 15 min. with no flow condition and perform Auto Zero calibration

Procedure (see section 5.3.7 “Zero Calibration”).

Lower the flow through GFM2 within calibrated range or shut down

the flow completely. The swamping condition will end automatically.

Return GFM2 to factory for repair.

Check maximum flow range on transducer’s front panel and make

required flow adjustment.

Unscrew the inlet compression fitting of the meter and reinstall

RFE (see section 6.2.2). NOTE: Calibration accuracy can be

Return GFM2 to factory for repair.

9.2 Troubleshooting Guide

Page 12