25

English

do it, set a maximum stroke rate and leave your power

tool to run idle�

Pendulum rate selection

[STS05-55 DV, STS06-80 D, STS06-85 DV]

Pendulum rate facilitates selecting the optimal sawing

regime (feed velocity, the appearance of the saw cut,

etc�) for the processed material�

With each downward move the saw blade 12 is driven

back from the blank part which improves the release of

the sawdust, reduces the heating up and increases the

operating life of the saw blade 12� Moreover the reduc-

tion of the feed force allows the worker to operate the

instrument without getting tired�

The degree of the pendulum strike may be changed

when operating the power tool� The lever for pendu-

lum stroke adjustment 9 allows setting four steps of the

pendulum stroke:

Step 0:

No pendulum action;

Step I:

Small pendulum action;

Step II:

Medium pendulum action;

Step III:

Large pendulum action�

It is recommended to consider the following rec-

ommendations when selecting the degree of the

pendulum rate:

•

when the edge of the saw cut must be exact and

clean, select small pendulum rate or switch the pen-

dulum rate off;

•

switch the pendulum rate off when processing thin

(sheet metal, sheet plastic, etc�) or hard materials

(alloy-free steel, non-ferrous metals, etc�);

•

when sawing soft materials (soft wood, etc�) se-

lect large pendulum rate; it will increase the speed

of the operation, however the quality of the saw cut

may be reduced�

It is recommended to make a test saw

cut using a spare piece of the blank part

(made of the same material as the blank

part to be processed) after the pendulum

rate is selected.

Protection against contact with saw blade

Contact protector prevents accidental contact with saw

blade 12 and improves safety of work performance�

Recommendations

on the power tool operation

Selecting the saw blade

Saw blades 12 of T-type may be used

with all of the jigsaw models.

Before starting the operation, please select the appro-

priate type of the saw blade 12 which should corre-

spond to the sawed material, sawing regime and the

quality of the edge of the saw cut� The designation of

the saw blade is printed on the package; you may also

ask the salesperson�

General guidelines for cutting

Make a test saw cut using a spare piece of

the blank part (made of the same material

as the material of the blank part) in order

to make sure that the saw blade 12, the

sawing speed and the pendulum strike have been

selected appropriately.

•

Make sure that the blank part is tightly fastened and

that all of the metal pieces (nails, screw nails, etc�)

have been removed from it�

•

Turn the power tool on before the saw blade 12 comes

in contact with the blank part� Do not use extra force; the

operation requires some time� Extra force will not speed

up the operating process, but it will overload the tool�

•

When the teeth of the saw blade 12 are too large

for the blank part (excessive vibration, splitting and

chipping of the processed surface will serve as a sign

of the teeth being too large), turn off the power tool

immediately and replace the saw blade 12 with the ap-

propriate blade�

•

If the saw blade 12 jams during the operation, turn

off the power tool immediately and try to expand the

saw cut, then carefully remove the saw blade 12 from

the saw cut�

• After the cutting is finished, first turn the power tool

off and then remove the saw blade 12 from the saw cut�

When cutting certain materials (like met-

als), the saw blade 12 may heat up ex-

cessively, therefore it is recommended

to use cooling or lubricating substances

which are to be applied to the point where the saw

blade 12 comes in contact with the blank part.

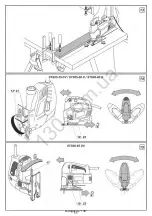

Plunge sawing (see fig. 10)

Plunge sawing may be used only when

sawing soft materials, such as wood,

plasterboard, etc. This operating tech-

nique facilitates sawing the holes

without preliminary drilling - the saw blade 12 cuts

through the blank part on its own. This technique

requires certain skill and may be applied using

short saw blades 12.

•

Position the power tool on the front edge of the base

plate

10

(see fig. 10) and turn it on. Slowly plunge the

blank part with the saw blade 12 by pressing the power

tool to the blank part�

•

Once the saw blade 12 cuts through the blank part

return the power tool into its normal operating position

and continue cutting along the marked line�

Sawing with guide bar for parallel cutting / circle

cutting

Circle cutting (see fig. 11)

[STS05-55 DV, STS06-80 D, STS06-85 DV]

Guide bar for parallel cutting / circle cutting

16

allows

circular sawing at a set radius�

Autogoods “130”

130.com.ua

Содержание STS05-55 DV

Страница 2: ...Autogoods 130 1 3 0 c o m u a ...

Страница 6: ...5 Autogoods 130 1 3 0 c o m u a ...

Страница 7: ...6 Autogoods 130 1 3 0 c o m u a ...

Страница 8: ...7 Autogoods 130 1 3 0 c o m u a ...

Страница 9: ...8 Autogoods 130 1 3 0 c o m u a ...

Страница 10: ...9 Autogoods 130 1 3 0 c o m u a ...

Страница 11: ...10 Autogoods 130 1 3 0 c o m u a ...

Страница 12: ...11 Autogoods 130 1 3 0 c o m u a ...

Страница 149: ...148 Autogoods 130 1 3 0 c o m u a ...

Страница 150: ...149 Autogoods 130 1 3 0 c o m u a ...

Страница 151: ...150 Autogoods 130 1 3 0 c o m u a ...

Страница 152: ...151 Autogoods 130 1 3 0 c o m u a ...

Страница 153: ...152 Autogoods 130 1 3 0 c o m u a ...

Страница 154: ...153 Autogoods 130 1 3 0 c o m u a ...

Страница 155: ...154 Autogoods 130 1 3 0 c o m u a ...

Страница 156: ...155 Autogoods 130 1 3 0 c o m u a ...

Страница 157: ...Autogoods 130 1 3 0 c o m u a ...