9

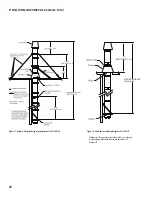

OPENING DIMENSIONS FOR WALL/ROOF PENETRATION

FOR MODEL DSD/DSLD

Inside

Diameter

Wall Thimble

(WT)

Wall

Thimble

Insulated

(WTI)

Roof

Thimble

(RT)

Roof

Thimble

Insulated

(RTI)

3”

12x12

13x13

9x9

13x13

4”

11 x 11

12 x 12

8 x8

12 x 12

5”

12 x 12

13 x 13

9 x 9

13 x 13

6”

13 x 13

14 x 14

10 x 10

14 x 14

7”

14 x 14

15 x 15

11 x 11

15 x 15

8”

15 x 15

16 x 16

12 x 12

16 x 16

9”

16 x 16

17 x 17

13 x 13

17 x 17

10”

17 x 17

18 x 18

14 x 14

18 x 18

12”

19 x 19

20 x 20

16 x 16

20 x 20

14”

22 x 22

22 x 22

18 x 18

22 x 22

16”

24 x 24

24 x 24

20 x 20

24 x 24

18”

26 x 26

26 x 26

22 x 22

26 x 26

20”

28 x 28

28 x 28

24 x 24

28 x 28

22”

30 x 30

30 x 30

26 x 26

30 x 30

24”

32 x 32

32 x 32

28 x 28

32 x 32

26”

40 X 40

40 X 40

32 x 32

32 X 32

28”

42 X42

42 X 42

34 x 34

34 X 34

30”

44 X 44

44 X 44

36 x 36

36 X 36

32”

46 X 46

46 X 46

38 x 38

38 X 38

34”

48 X 48

48 X 48

40 x 40

40 X 40

36”

50 X 50

50 X 50

42 x 42

42 X 42

Table 11: Opening Dimensions for Model DSD & DSLD.

Dimensions are in inches.

CONDENSATE DRAINS

When an internal condensate drain is NOT part of the appliance:

1. A Drain length (DL) or a Tee with a drain tee cap (DTC) is strongly recom-

mended. Install this drain as close as possible to the appliance flue collar.

2. A condensate drain is required for every 30 feet of horizontal vent and

at the bottom of a vertical stack.

3. Use the Drain length for a straight horizontal run. Rotate the fitting so

that the drain tube is as vertical as possible.

4. Use a Tee at a transition from horizontal to vertical, and attach the Drain

Tee Cap to the appropriate branch of the tee.

5. A condensate drain tube kit is available to direct the condensate to an

appropriate location. A trap loop must be formed into the drain hose

and must be a diameter that is at least four times the appliance’s rated

stack pressure in inches of water column or minimum 3 inches. Secure

the loop with a cable tie.

6. Flue gas condensate can have a low (3 to 5) PH level, follow all local and

national codes and regulations for the draining of acidic condensate.

7. In cold climate, do not install a condensate drain on the exterior of the

building. Doing so may result in dangerous icy conditions on surfaces near

the drain and may cause damage to the vent system and the building

exterior. DuraVent™ will NOT be held liable for any injury or property

damage due to formation of ice.