22

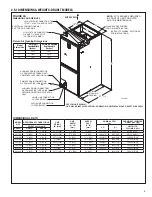

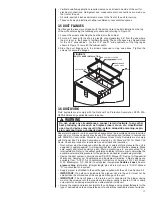

3.13.1 CONFIGURING UNIT FOR 208 VOLT POWER

The control transformer in 208/240V air-handlers must be configured in the field to oper-

ate on a 208 volt electrical supply to assure adequate control voltage (24+ volts) with the

reduced supply voltage. The units are shipped from the factory for 220-240 volt appli-

cations. For 208 volt applications, disconnect electrical power to the unit and remove

the blower access panel and then the control box cover located on the blower housing.

Then remove the insulated cap from the 208 volt transformer terminal and move the

BLACK wires that are connected to the 240 volt transformer terminal to the 208 volt

transformer terminal. Plug the insulated cap onto the transformer 240V terminal.

3.13.2 GROUNDING

• This product must be sufficiently grounded in accordance with National Electrical

Code (C.E.C. in Canada) and any applicable local ordinance.

• Grounding may be accomplished by grounding metal conduit when installed in accor-

dance with electrical codes to the unit cabinet.

• Grounding may also be accomplished by attaching ground wire(s) to ground lug(s)

provided in the unit wiring compartment.

• Ground lug(s) are located close to wire entrance on left side of unit (upflow). Lug(s)

may be moved to marked locations near wire entrance on right side of unit (upflow), if

alternate location is more convenient.

• Use of multiple supply circuits require grounding of each circuit to lug(s) provided in unit.

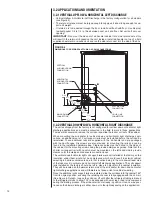

3.13.3 POWER WIRING

It is important that proper electrical power is available for connection to the unit model being

installed. See the unit nameplate, wiring diagram and electrical data in the installation instructions.

• If required, install a branch circuit disconnect of adequate size, located within sight of, and readi-

ly accessible to the unit.

• IMPORTANT:

Units with electric heater kits installed may be equipped with one, two, or three

30/60 amp circuit breakers. These breaker(s) protect the internal wiring in the event of a short

circuit and serve as a disconnect. Circuit breakers installed within the unit do not provide

over-current protection of the supply wiring and therefore may be sized larger than the branch

circuit protection.

• Supply circuit power wiring must be 75°C minimum copper conductors only. See Electrical Data

in Sections 3.13.5 and 3.13.6 for ampacity, wire size and circuit protector requirement. Supply

circuit protective devices may be either fuses or “HACR” type circuit breakers.

• Field power wiring may be connected to either the right, left side or top. Three

7

/

8

”, 1

3

/

32

”, 1

31

/

32

” dia.

concentric knockouts are provided for connection of power wiring to unit.

• Field power wiring is to be connected to the power terminal block in unit control compartment.

• For units equipped with an electric heater kit, field power wiring is to be connected to the heater

kit breaker, terminal block, or pullout disconnect terminals and the power wiring pigtail from the

heater kit is to be connected to the unit power terminal block in the unit control compartment.

Refer to installation instructions provided with the heater kit for additional details.

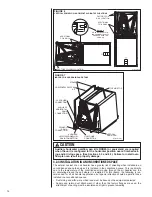

WARNING

The unit must be permanently grounded. Failure to do so can result in electri-

cal shock causing personal injury or death.

!

S

U

P

P

L

Y

W

I

R

E

L

E

N

G

T

H

F

E

E

T

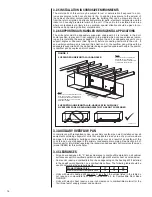

SUPPLY CIRCUIT AMPACITY

NOTE: WIRE BASED ON COPPER CONDUCTORS 75°C MINIMUM RATING.

FOR MORE THAN 3 CONDUCTORS IN A RACEWAY OR CABLE, SEE

N.E.C. FOR DERATING THE AMPACITY OF EACH CONDUCTOR.

12

12

14

14

15

10

10

12

12

20

8

10

10

10

25

8

10

10

10

30

8

8

8

8

35

6

8

8

8

40

6

6

8

8

45

6

6

6

6

50

4

6

6

6

60

4

4

4

4

70

3

4

4

4

80

3

3

3

3

90

2

3

3

3

100

2

2

2

2

110

1

1

1

1

125

0

0

0

0

150

00

00

00

00

175

3.13.4 COPPER WIRE SIZE - AWG. (3% VOLTAGE DROP)

200 [61]

150 [46]

100 [30]

50 [15]

3.13.5.1 ELECTRICAL DATA – BLOWER MOTOR ONLY – WITHOUT ELECTRIC HEAT: DRAH1T

MODEL

DRAH1T

VOLTAGE

PHASE*

HERTZ

HP

RPM

SPEEDS

MOTOR

AMPS

MINIMUM

CIRCUIT

AMPACITY

MAXIMUM

OVERCURRENT

PROTECTION

2417AS

208/240

1 & 3

60

1/3

300-1100

4

1.6

2

15

3617AS/3621AM/3621AH

1/2

300-1100

4

2.8

4

15

4821AS/4821AM

3/4

300-1100

4

4.0

5

15

6021AS/6024AS/4824AS

3/4

300-1100

4

4.6

6

15