19

3.9.3 BRAZING

Air inside the tubing and coil should be displaced with dry nitrogen prior to the brazing

process to prevent the formation of harmful copper oxide inside the tubing. It is very

important not to pressurize the system with nitrogen while brazing or pin-hole leaks will

form in the braze joint. This is accomplished by removing the gauge port valve core on

one of the outdoor unit service valves to allow the pressure to be relieved as the heat-

ed nitrogen expands. Fill the system with dry nitrogen through the other service valve

gauge port and then turn the nitrogen flow off just before brazing is begun.

Protect the TXV, copper to aluminum suction header joint, and outdoor unit service

valves from overheating using a wet rag or heat sink compound. Leave the wet rag or

heat sink material in place until the joint and surrounding tubing cools down to a safe

temperature. Double tip torches can help minimize brazing time and heat conduction

to the heat sensitive components if the flame is turned down and held on the joint just

long enough to make the braze joint. With both single and double tip torches, turning

the flame up too much and keeping the flame on the joint too long will damage the heat

sensitive components even when a wet rag or heat sink compound is used.

Use a sheet metal shield to protect the cabinet’s paint from the torch flames during the braz-

ing process. The vapor line insulation should be pushed back on the line about 12 inches

from the joint and retained to prevent it from igniting or melting during the brazing process.

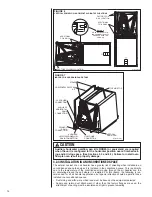

After the refrigerant brazed connections are made at the air-handler and the tubing has

cooled down sufficiently, replace the coil section access panel if it has been removed

and seal the air gap around the connection stubs with the foam rubber gasket included

in the air-handler parts bag. Peel the self-adhesive backing off of the foam gasket and

position it around the stubs with the adhesive side toward the cabinet, then press it firm-

ly against the cabinet. The gasket is split to allow it to go over the stubs after the refrig-

erant tubes are brazed to the stubs. (See Figure 12 in Section 3.10)

After the foam gasket has been installed, the vapor line insulation should be pulled back

in place so it contacts the air-handler cabinet to prevent condensate from forming on the

cold tube and dripping off. A loosely fitting zip-tie placed around the insulation ½” from

the end can be used to hold it in place so it doesn’t move away from the cabinet. For

air-handlers with TXV’s, a section of the insulation will need to be cut out to make room

for the externally mounted TXV bulb.

(See Section 3.10)

Once the bulb is mounted,

insulate the bulb with the foam insulation included in the air-handler parts bag, making

sure none of the vapor line is uninsulated.

3.9.4 LEAK TESTING

After all braze joints are completed, replace the valve core removed when purging with

nitrogen and then leak test the system by pressurizing to 150 psig with dry nitrogen and

allow the system to sit for at least 15 minutes (longer if possible) to assure the pressure

does not drop.

3.9.5 EVACUATION

If no leaks are detected, evacuate the system down to 500 microns or below before

charging the system or opening the service valves on the outdoor unit which will release

the charge stored in the outdoor unit into the line set and air-handler coil. Failure to

reach 500 microns of vacuum is a sign of a leak or excessive moisture inside the system.

3.9.6 REFRIGERANT CHARGING

Once the evacuation process is completed, break the vacuum with the refrigerant from a

refrigerant cylinder or with refrigerant stored in the outdoor unit by opening the outdoor

unit service valves. The charging process cannot be completed until the remaining

steps in the installation process are completed and the indoor air-flow is adjusted to the

proper level. See Section 4.7 for further details.

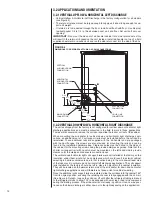

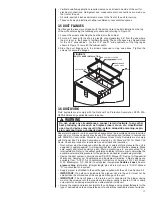

3.10 TXV SENSING BULB ATTACHMENT

IMPORTANT:

DO NOT perform any brazing with the TXV bulb attached to the vapor

line. After brazing operations have been completed and the tubing has cooled to the

touch, clamp the TXV bulb securely on the vapor line at the 10 to 2 o’clock position (see

Figures 11 and 12) with the strap provided in the parts bag. Insulate the TXV sensing

bulb and suction line with the provided pressure sensitive insulation (size 4” × 7”) and

secure with provided wire ties.

IMPORTANT: TXV sensing bulb should be located on a horizontal section of suc-

tion line, just outside of coil box. The copper sensing bulb must never be placed

on any aluminum tube as this will result in galvanic corrosion and eventual failure

of the aluminum tube.