CONDENSER HEAD PRESSURE CONTROL

General

All units require some means to keep the condensing pres-

sure high enough to insure adequate expansion valve feed

to the cooler to prevent low side pressure trips, particularly

during cold starts.

THE RECOMMENDED SPD-SD REMOTE AIR COOLED CON-

DENSER

Standard Factory Installed Fan Cycling

This commonly applied scheme cycles condenser fans “on”

and “off “ in response to head pressure to maintain the head

pressure within an acceptable range for proper system op-

eration. This method will permit starting and sustained run-

ning to 30°F ambient.

T

he minimum ambient shown above reflects the performance

of the condenser surface exposed to the operational fan(s)

as well as that portion of the surface rejecting heat by natu-

ral convection with related fans “off”. To further assist low

ambient starts, all fans are held “off” until the head pressure

reaches 260 psig. This alone cannot insure sustained opera-

tion if the system load is not high enough to produce the

minimal pressures required.

Operational Variable Speed Fan Control

This scheme utilizes fan cycling but also adds speed control

to the lead fan of each refrigerant circuit. This feature not

only serves to stabilize the head pressure between normal

fan staging but also allows for virtually “no fan” operation

down to 0°F ambient.

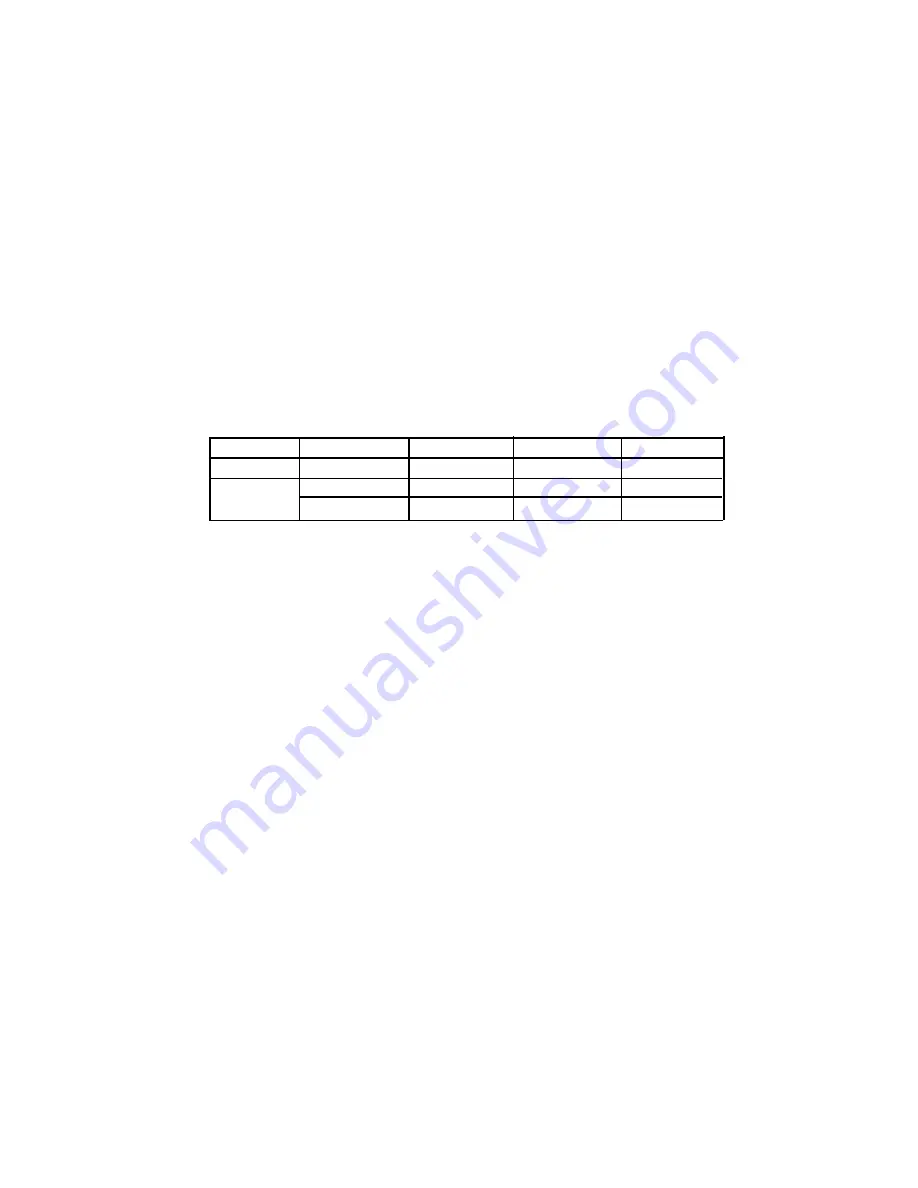

SPD-SD

FAN CYCLING CONTROL SETTINGS

CUT-IN/CUT-OUT)PSIG)

HRSC100-150

SEQUENCE OF OPERATION (TYPICAL) MODELS

UNIT

FCP1

FCP2

FCP3

FCP4

070

260/160

275/175

285/210

295/235

FCP1 & 2

FCP3 & 4

FCP5 & 6

FCP7 & 8

260/160

275/175

285/210

295/235

The following sequence of operation is typical for all Electro-

mechanical HRSC models. Refer to the wiring diagram fur-

nished with the unit for specific information.

Important Note!

With all the control circuit switches (SW1-SW3) in the “off”

position and the staging thermostat (T1) to its highest tem-

perature, there must be a 115 volts supplied to the compres-

sor crankcase heaters (CCH1,2) for a minimum of 24 hours.

Preliminary Sequence

Close the main power disconnect switch. Check to see that

the red indicating light on the phase loss monitor (PLM1) is

lit. (Note: There will be two phase loss monitors, (PLM1) and

(PLM2) on dual power block models). This light must be on

to indicate proper phase rotation for the compressors. If the

light is not on, disconnect the main power and reverse any

two phase legs at the Main Incoming Power Terminal Block.

(Warning! DO NOT REVERSE THE LEADS ON THE PHASE

LOSS MONITOR FOR THIS WILL ALLOW THE COMPRESSORS

TO RUN BACKWARDS, CAUSING SEVERE DAMAGE, AND

WILL VOID THE COMPRESSOR WARRANTY!).

The crankcase heater relay contacts are closed and are sup-

plying power to the compressor crankcase heaters.

Control power goes through the control panel circuit breaker

(CB1) and customer supplied control (if supplied).

Start up the chilled water pump. An auxiliary contact on the

chilled water pump closes. The water flow is confirmed when

the water flow switch completes the electrical circuit. Set

the thermostat (T1) to the desired leaving water tempera-

ture (e.g. 44°F.). Set point Adjustment is accomplished di-

rectly on the control.

9

Place the three (3) control circuit switches (SW1-SW3) in the

“On” position, thus energizing the balance of the control

circuit. The system will be in the “Time-In” mode for five

minutes before the first compressor will start.

The low temperature freezestat (T2) must also be satisfied to

allow compressor operation.

Stage 1 Loading

Upon demand for cooling, the first step of the staging ther-

mostat (T1) will close energizing relays (R1) and time delay

(TD1). If all the safety controls and switches are closed, (see

“Safety Controls” section for more detail) the control circuit

for Compressor No. 1 will energize, allowing the compressor

to start. Power is supplied to condenser fan interlock termi-

nal CT19 and CT2 to enable the remote condenser fan cir-

cuit. Relay (R5) will energize, closing the normally open set

of contacts, which energizes the liquid line solenoid valve

(SOL1). Another set of normally open contacts on (R5) pro-

vide a series interlock with all the safety and operating con-

trols, which will lockout the compressor if any safety trips

during normal operation. (See Note 6 on Wiring Diagram).

The last set of normally closed contacts on (R5) open and de-

energizes (CCH1).

Time Delay (TD1) has two (2) sets of contacts: The first set of

(TD1) normally closed contacts provides a 30 second jumper

around the low pressure control (LP1) to prevent short cy-

cling during start-up. The second set of (TD1) normally closed

contacts powers the unloader solenoid (UL3-1) which holds

the compressor in the full unload position for 30 seconds.

After (TD1) times out (30 seconds), the contacts for the

unloader solenoid (UL3-1) open and the normally open con-

tacts close, which energizes the relay (R3). Upon energizing

relay (R3) the normally open contacts of relay (R3) are closed,

allowing the thermostat (T1) to energize the load (UL1-1)

and the unload solenoid (UL2-1) upon demand.

140

Содержание HRSC - D

Страница 20: ...19 TYPICAL HRSC 150 POWER WIRING 460 3 60 COMPRESSOR MOTORS 1 2 SEE NOTE 5...

Страница 21: ...20 TYPICAL HRSC 150 CONTROL WIRING Electrical Mechanical...

Страница 22: ...21 TYPICAL HRSC 150 CONTROL WIRING Optional Micro Computer Controller...

Страница 23: ......

Страница 29: ......

Страница 30: ......