Scissor Lift Inspection and Maintenance

Draper recommends inspecting the Scissor Lift at least annually or every 300 cycles—whichever comes first.

A recommended maintenance schedule includes:

• Cables:

Check for fraying.

• Drive Chain Gears:

Check for

rust, breaks, secure attachment.

• Fasteners along scissor arm assemblies:

Make sure they are not loose.

If any are loose, hand tighten the nuts.

Please Note:

There is no need to tighten nut in the top scissor which

slides back and forth in the side slot in the lift. Tightening this fasteners

assembly will cause the unit to lock up and lead to damage to the unit.

• Closure:

Ensure threaded rod remains

seated firmly in the closure panel

corners, and that nuts remain tight. If

they are loose, tighten them.

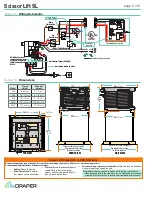

Section 15 -

Wiring Schematic

Model

Closed

Height

Extended

Height

SL4

8"

(20.3cm)

4'

(121.9cm)

SL6

10"

(25.4cm)

6'

(182.9cm)

SL8

12"

(30.4cm)

8'

(243.8cm)

SL10

14"

(35.6cm)

10'

(304.8cm)

SL12

16"

(46.6cm)

12'

(365.8cm)

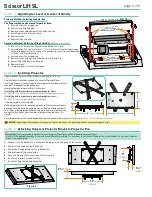

Section 16 -

Dimensions

There are four sizes of closure.

See separate instructions

for details and dims.

FRONT VIEW

SIDE VIEW

There are four sizes of closure.

See separate instructions

for details and dims.

See

Table

"A"

TOP VIEW

20

"

(527 mm)

20"

(508 mm)

24

"

(624 mm)

20

"

(524 mm)

16

"

(419 mm)

22

"

(583 mm)

"

(11 mm)

x 4

There are four sizes of closure.

See separate instructions

for details and dims.

FRONT VIEW

SIDE VIEW

There are four sizes of closure.

See separate instructions

for details and dims.

See

Table

"A"

TOP VIEW

20

"

(527 mm)

20"

(508 mm)

24

"

(624 mm)

20

"

(524 mm)

16

"

(419 mm)

22

"

(583 mm)

"

(11 mm)

x 4

N

U

C

D

Dashed wiring by electrician

11

5V

AC

,

Su

ppl

y

WH

BK

BK

WH

GN

WH

Low voltage wiring by others

WH

Encoder

RD

BK

RD

WH

RD

WH

BK

WH

RD

BN

RD

WH

BK

YL

YL

/

GN

RD

BK

BK

OR

Up

Limit Switch

NC

NC

BK

BN

NC

Down

Limit Switch

Delay Switch

(on position)

RD

BK

OR

RD

RD

BK

BL

YL/GN

BK

Motor

Up

Down

BK

BK

BK

WH

OR

RD

BK

BK

WH

OR

RD

AC

AC

COM

N.O.

N.C.

BK

WH

RD

OR

Optional Delay Assembly

115VAC, 12A 60 Hz Outlet

Run Cap

45 MFD

2 Cond. Cable

Attached to

lower pan

Low Voltage Trigger (6-24 VDC)

Wall Switch

Key Switch

RP/RQ Bus Ports for

remote controls such

as IR Eye, RF Receiver,

LED Wall Switch and

RS232.

page 8 of 8

Scissor Lift SL