3

WORKING ADVISE WITH SAFETY SWITCH

22

MAINTENANCE ADVICE

23

WARRANTY

24

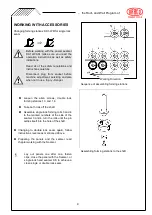

When working at the wall or roof, ensure

that everything conforms to the local health

and safety regulations.

Before plugging in and using Seamer check plug and

cable also accessories if damaged.

Consider work area environment in rain or

snow, working on Metal Roofs is prohibited

after DIN18339.

Any damage on Seamer, send machine in to the

manufacturer for servicing.

DANGER / ACCIDENT

Check label for voltage, the electric mains

connection must correspondent.

Don’t expose the Seamer to rain or snow,

the Power Seamer can be used in damp

locations on account of water-protection

resistance after IP 54

The Seamer must be operated on a

grounded socket only, to guard against an

electric shock. Danger due to electric shock.

Guard against electrical shock.

Disconnect plug from socket, before

machine - adjustment or servicing and when

not in use. Injury

– Danger.

Do not transport Seamer or Metal Box with

a lifting crane.

Operate Seamer only when located on top of

the panel. Injury.

Working overhead with the seamer is not

allowed.

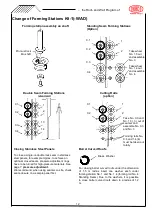

Ensure that the forming stations are

positioned correctly, (numbers). Use Original

Forming Rolls only.

The Seamer must work freely without

force, do not push or pull and do not sit or

stand on top of the machine.

Danger, accident.

Before profiling check the rolls, for right

position, that they are located in the pin and

the screws tight.

The Operator must secure himself when

working with the machine.

Danger Accident.

Lifting eyes are provided to enable a safety

rope or cable to be fitted, especially when

working on vertical claddings or on a steep

... the Roof- and Wall Program of

Safetey Indicators for

Users and Operators