22

Instructions how to work with the DUAL - Safety Switch K9-1 DF

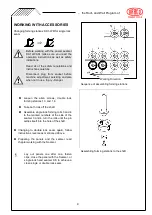

1. Check if machine is equipped with a DUAL-Safety Switch K9-1 KF.

2. Plug must be inserted to the socket (No. 3) see label, K9-DF,

electronic switch box.

3. Bottom seam switch, push to the top and insert pin into hole (No.8). This activates

the seamer.

4. Push red switch to on (No. 1) light burns.

5. Choose forward, reverse or stop function with switch (No. 6). For forward operation, push

lever switch to the top.

6. Push seam switch to the top and insert pin into hole (No. 9) to activate the machine.

7. Push start up button (No. 2), all forming stations must turn.

ATTENTION

When working with the dual safety switch, the pin must be disconnected; otherwise seamer will

not stop at the end of the seam. Check spring tension of seam lever switch at all times. Danger

machine can fall off the roof.

8. Therefore insert the pin to hole (No. 9) for non-operation.

9. Set seamer and seam switch on top of the seam.

10. Push start up button (No. 2).

11. With the variable speed knob (No. 5) it is possible to increase the seaming speed from

5,5 m/min up to 13 m/min.

12. At the end of the ridge, eave or any other obstructions the machine shuts off automatically.

13. Seam switch below, shuts off at the end of the ridge, the front switch at any other

obstructions.

... the Roof- and Wall Program of

Hole No. 8

Seam lever

switch

down

position

Front

switch

Hole No. 9

Seam lever

up position