11/21

NT 1401-F00 12.05 Cold front outlet Intercooler TYPHON e

STEP 3

Close all valves and proceed to pressurize the tank and

discharge the cargo.

3.5 SHUTTING DOWN PROCEDURE - Vehicle

Mounted

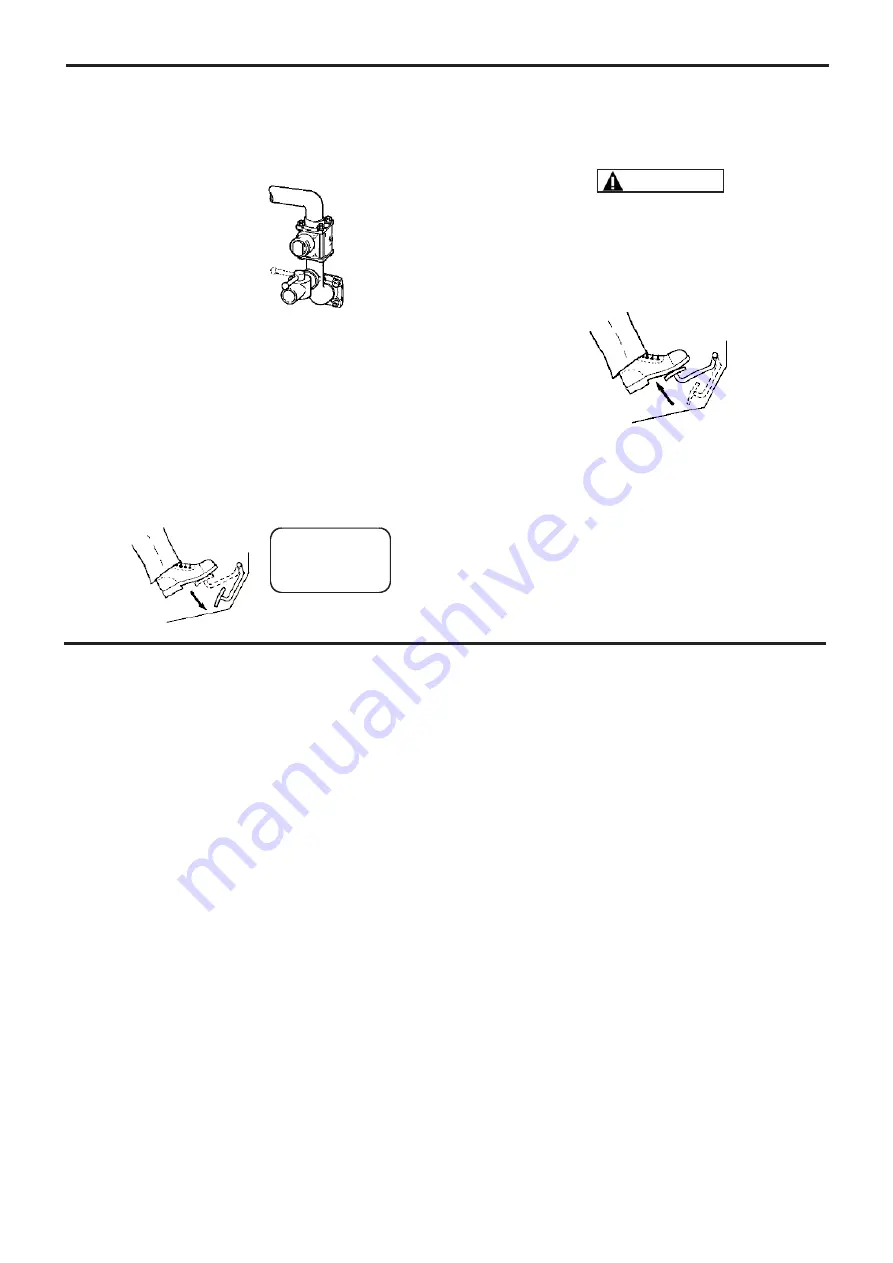

STEP 1

Depress the clutch and disengage the PTO.

STEP 2

Reduce engine speed to idle.

ALWAYS DISENGAGE THE DRIVE BEFORE SLOWING ENGINE

DOWN.

STEP 3

Release the clutch.

NOTICE :

DO NOT attempt to restart the compressor in the follow-

ing instances :

a. If there is still pressure or vacuum in the system. In

this instance, open the vent valve first, than restart the

compressor. Once the pump is up to speed, close the

vent valve slowly.

b. If the compressor input speed is too slow.

CAUTION

PTO

OFF

NOTICE :

THE COMPRESSOR MUST OPERATE AT FIXED SPEED WITHIN

THECOMPRESSOR MODEL SPEEDLIMITS. SPEED MUST

REMAINCONSTANT THROUGHOUT THE OFF LOADING OPE-

RATION.

« FERME »

CLOSE

33.. P

PA

AC

CK

KA

AG

GE

E O

OP

PE

ER

RA

AT

TIIO

ON

N ((ccoonnttiinnuueedd))

44.. M

MA

AIIN

NT

TE

EN

NA

AN

NC

CE

E

4.1 Maintenance schedules

After each water cleaning of the truck or compressor

Always run the compressor for 15 minutes to remove

any water that inadvertently gets into the piping.

DO NOT fog or introduce anti-corrosive liquids into the

compressor to prevent corrosion. Use of liquids in the

compressor will cause failure.

After the first 50 hours of operation

Change compressor oil.

After 300 hours and at least every year

Change compressor oil.

Weekly

1.

The compressor should be run once a week for at

least 15 minutes to prevent moisture from collecting

inside. This will reduce the risk of corrosion damage to

the compressor and other equipment in the piping.

2.

Inspect and clean air filter. Clean the compressor

external surfaces and cooling fins. Inspect DAILY if

operating in dirty or severe environment. Check the

condition of the inlet filter hose for splits and tears.

Replace or repair as necessary.

3.

Inspect compressor, system piping and components.

Clean or repair as necessary.

4.

Check power transmission line (pulley, shaft, torque

limitor...).

Per manufacturer’s recommendations

Lubricate the universal seal.

Monthly

1.

Check the relief valve(s) for wear and proper settings.

Replace or adjust as necessary.

2.

Check that the check valve works properly, replace as

necessary.

4.2 Compressor oil draining procedure

Compressor maintenance is limited to a periodic oil

change.

For oils recommended, see § 3.1.

Unscrew and remove the oil filter with its seal. Drip-drain

all the oil contained in the casing.

Carefully clean the oil filter with solvent. Blow out all

impurities with a compressed air blast.

After checking that no particles remain in the filter, reins-

tall it making sure that the seal is in good condition.

Fill the compressor. See § 3.2.