Lit. No. 72936, Rev. 01

12

October 15, 2019

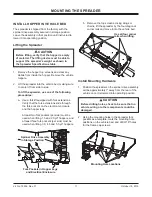

2. Install the frame spacer between the end cap of the

hopper trough and the front of the vehicle bed.

Install Tie-Down Straps

Run straps from the tie-down loops from the spreader

hopper diagonally outward to the vehicle frame.

NOTE: Periodically throughout the snow and ice

control season, verify that mounting devices

are secure.

NOTE: Pay special attention when drilling or

clamping dissimilar metals to aluminum bodies.

Galvanic corrosion can occur if not handled

properly. Contact vehicle manufacturer for

recommended attachment practices.

3. Secure the spreader to the vehicle bed through

the fork pockets, using

at least

one fastener per

fork pocket. Use 1/2" hardware as required by the

vehicle application.

NOTE: If the mounting holes are not directly over

the vehicle box supports, the vehicle bed must

be braced to the frame to prevent buckling or

deforming the vehicle bed.

Construct and Install Frame Spacer

1. Measure the distance from the hopper trough end

cap to the front of the vehicle bed. Construct a

frame spacer from 2" x 8" lumber to

fi

t that area.

MOUNTING THE SPREADER

CAUTION

Failure to install the frame spacer could result

in damage to the spreader and/or vehicle.

Frame Spacer Built to Fit

WARNING

Spreader shall be bolted to vehicle frame. Do

not rely on tie-down chains or straps alone to

hold spreader in vehicle.

Determine

Distance

Fit to vehicle.

Measured

Distance

Front of

Truck Bed

Measure distance.

Trough

End Cap