Maintenance Section

-147-

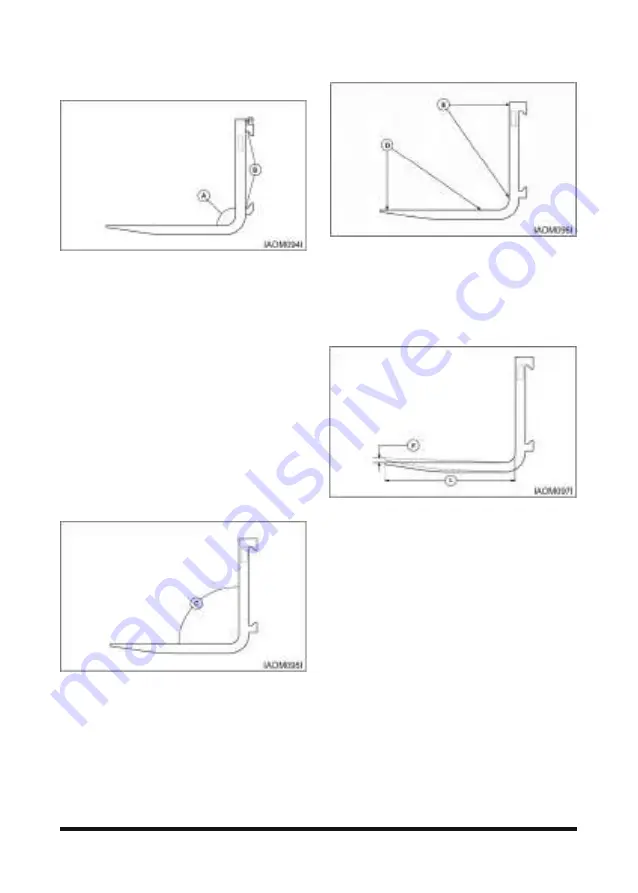

Fork – Inspect

Forks should be inspected, at a minimum, every 12

months. If the truck is being used in a multi-shift or

heavy duty operation, they should be checked every six

months.

1. Inspect the forks carefully for cracks. Special

attention should be given to the heel section (A), all

weld areas and mounting brackets (B). Inspect the

top and bottom hooks on forks used on hook type

carriages and tubes on shaft mounted forks.

Forks with cracks should be removed from service.

"Wet Test" magnetic particle inspection is generally

preferred due to its sensitivity and the ease of

interpreting the results. Portable equipment is

usually recommended so it can be moved to the lift

truck.

Inspectors should be trained and qualified in

accordance with The American Society for Non

Destructive Testing, Level II Qualifications.

2. Check the angle between the upper face of the

blade and the front face of the shank. The fork

should be withdrawn from service if angle (C)

exceeds 93 degrees or deviates by more than 3

degrees from an original angle other than 90

degrees, as may be found in some special

application forks.

3. Check the straightness of the upper face of blade

(D) and the front face of shank (E) with a straight

edge.

The fork should be withdrawn from service if the

deviation from straightness exceeds 0.5 percent of

the length of the blade and/or the height of the

shank respectively 5 mm/1000 mm (0.18"/36").

4. Check the difference in height of one fork tip to the

other when mounted on the fork carrier. A difference

in fork tip height can result in uneven support of the

load and cause problems with entering loads.

The maximum recommended difference in fork tip

elevation (F) is 6.5 mm (0.25") for pallet forks and 3

mm (0.125") for fully tapered forks. The maximum

allowable difference in fork tip elevation between the

two or more forks is 3 percent of blade length (L).

Replace one or both forks when the difference in

fork tip height exceeds the maximum allowable

difference. Contact your local DOOSAN Lift Truck

Dealer for further information.

https://www.forkliftpdfmanuals.com/

Содержание D35S-5

Страница 2: ...https www forkliftpdfmanuals com ...

Страница 31: ...Safety Section 29 Lean away from the direction of fall Lean forward https www forkliftpdfmanuals com ...

Страница 41: ...General Section 39 Capacity Chart D G 35S 5 D G 40S 5 D G 45S 5 https www forkliftpdfmanuals com ...

Страница 42: ...General Section 40 Capacity Chart D G 35S 5 D G 40S 5 D G 45S 5 https www forkliftpdfmanuals com ...

Страница 45: ...General Section 43 Capacity Chart D G 40SC 5 D G 45SC 5 D G 50SC 5 https www forkliftpdfmanuals com ...

Страница 46: ...General Section 44 Capacity Chart D G 40SC 5 D G 45SC 5 D G 50SC 5 https www forkliftpdfmanuals com ...

Страница 49: ...General Section 47 Capacity Chart D G 50C 2 D G 50C 5 https www forkliftpdfmanuals com ...

Страница 50: ...General Section 48 Capacity Chart with Side Shifter D G 50C 2 D G 50C 5 https www forkliftpdfmanuals com ...

Страница 196: ...https www forkliftpdfmanuals com ...

Страница 225: ...Safety Section 29 Lean away from the direction of fall Lean forward https www forkliftpdfmanuals com ...