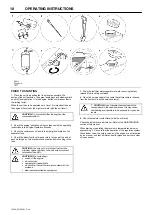

OPERATING INSTRUCTIONS

27

12/150_23136591

−

C en

DECOMMISSIONING

When the machine is to be permanently decommissioned or

dismantled, it is important to ensure that all hazard risks are either

eliminated or notified to the recipient of the machine. In particular:

−

Do not destroy batteries or components containing asbestos

without containing the materials safely.

Do not dispose of any pressure vessel that is not clearly marked

with its relevant data plate information or rendered unusable by

drilling, cutting etc.

Do not allow lubricants or coolants to be released into land

surfaces or drains.

Do not dispose of a complete machine without documentation

relating to instructions for its use.

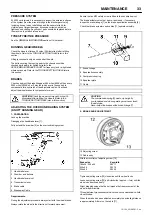

BUNDED BASE

Description

This machine is fitted with bund equipment to contain leakages and

spillages, which occur within the machine enclosure.

The bund will contain all fluids normally installed in the machine, plus

an additional 10%, when operated within 3 degrees of level.

Drains for engine water & oil and compressor oil are located at the

front corner of the machine

The rear air intake is covered to prevent rainwater ingress. Ensure

that the cover is not prevented from moving.

Draining of contaminated fluids

Contaminated fluid must be removed by authorized personnel only.

Captured fluids can be drained from the bund by uncoupling the

flexible pipe secured at the rear / side. This pipe must be re

−

secured

after draining.

Drainage of machine fluids

During maintenance operations drain machine fluids using the drain

ports indicated.

When cleaning of the fuel tank is needed, tank should be removed

from compressor.

Captured fluids can be drained from the bund by uncoupling the

flexible pipe secured at the rear / side. This pipe must be re

−

secured

after draining.

WARNING: Major leakages or spillages must be

drained before the machine is towed.

LONG TERM STORAGE RECOMMENDATIONS

(6 months or more)

SPARE AIRENDS

Long

−

term storage of airends should include filling the airend with

the standard compressor fluid, PRO

−

TEC, XHP605 or XHP405.

Upon installation of the airend, drain the storage oil from the airend

and proceed with the installation, assuring fresh oil is poured into the

intake prior to start up.

PORTABLE COMPRESSORS

Airend

−

Remove the intake connection and fill the airend intake with Doosan

compressor fluid PRO

−

TEC, XHP605 or XHP405.

Reconnect the intake connection.

Engine cooling system

−

Treat with rust inhibitor and drain. Check with engine dealer for

further recommendations.

Compressor Oil Filter/s

−

. fill with Doosan compressor fluid PRO

−

TEC, XHP605 or

XHP405.

General

−

Seal all openings with waterproof tape.

Place a desiccant in the exhaust pipes, engine and compressor air

intake pipes.

Loosen tension on belts, fan, airend etc.

Block axles so that the tires are off the ground and do not support

any weight.

Disconnect battery cables.

Drain the fuel system.

SHORT TERM STORAGE

Machines that stand unused for an extended period of time greater

than 30 days should:

be started and operated every 30 days. Operate long enough to

allow the engine and compressor to reach operating temperature.

have the service valve opened and closed to exercise the

machine from full load to idle RPM.

have the fuel tank drained to remove any water.

have the water drained from the fuel water separator.

Содержание 12/150

Страница 42: ...MACHINE SYSTEMS 40 12 150_23136591 C en ...

Страница 44: ...MACHINE SYSTEMS 42 12 150_23136591 C en WIRING DIAGRAM 23296643_B SHEET 2 ...

Страница 46: ...MACHINE SYSTEMS 44 12 150_23136591 C en WIRING DIAGRAM 23296643_B SHEET 3 ...

Страница 81: ......

Страница 82: ......