3

Table 1 - Oil Dam and COL to Shaft Clearance (Inches)

Shaft Diameter

2-15/16 3-17/16 3-15/16

4-7/16

4-15/16 5-7/16

Tip of oil dam to shaft

5/32

5/32

1/8

1/8

1/8

1/8

Shaft Diameter

6

7

8

9

10

12

Tip of oil dam to shaft

11/32

11/32

9/32

9/32

1/2

1/2

Tip of COL to shaft

1/4

5/16

5/16

5/16

5/16

13/32

3. INSTALLATION OF OIL RING (S)

Each ring is match marked and MUST NOT be interchanged.

Place oil ring(s) around lower liner and shaft. Install and tighten

four screws in each oil ring.

Oil dams can be adjusted, if necessary, to avoid contact with

oil ring. Loosen screws and move dam; bend base of dam, if

necessary, to obtain clearance in Table 1.

Oil shaft under oil ring(s). Make sure oil ring(s) rotate freely.

FOR BORES 6” THROUGH 12”:

Narrow leaf of COL will contact

oil ring inside wide groove as shown below. COL can be adjusted

to align leaf with wide oil ring groove. Loosen screws and move

COL; do NOT bend or distort COL. Tighten screws.

4. NON-EXPANSION BEARINGS WITH DODGE SPLIT

THRUST COLLARS (‘S’ LINERS ONLY)

Split thrust collars are available for ‘S’ liners only. Remove clamp

screws from collars. Remove jam screws and back out set

screws so they do not protrude into inside diameter of collar.

MATCH

MARKS

PART NO.

Place one half of collar on shaft with large chamfer next to shaft

shoulder. Rotate collar half around shaft and place other half in

position.

LARGE CHAMFER

NEXT TO

SHAFT SHOULDER

NOTE: Collar halves are match marked; do NOT assemble

halves with different marks.

Tighten clamp screws to torque specified in Table 2. Collar faces

MUST NOT be offset at split. Repeat for second collar.

Locate collars tight against shaft shoulders. This will allow

0.015

to

0.035 inch

total running clearance between collars and liner thrust

faces. Tighten set screws to torque specified in Table 2. Install and

tighten jam screws on top of set screws.

Table 2 - Torque Values for DODGE Split Thrust Collars (in.-lbs.) ft.-lbs.

Shaft Size

(inches)

2-15/16

3-7/16

3-15/16

4-7/16

4-15/16

5-7/16

Clamp

Screw

(96) 8

(96) 8

(96) 8

(96) 8

(204) 17

(204) 17

Set

Screw

(60) 5

(60) 5

(60) 5

(60) 5

(132) 11

(132) 11

Shaft Size

(inches)

6

7

8

9

10

12

Clamp

Screw

(360) 30

(360) 30

(900) 75

(900) 75 (1800) 150

(1800) 150

Set

Screw

(264) 22

(264) 22

(264) 22

(264) 22 (1320) 110

(1320) 110

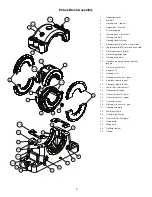

Содержание SLEEVOIL RXT

Страница 9: ...9 Oil Ring Assembly 22A 22B 22C...

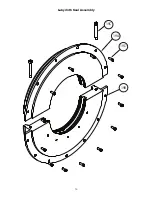

Страница 10: ...10 Labyrinth Seal Assembly 19C 19A 19D 19B...

Страница 11: ...11 Shim Collector Oil Leaf Oil Dam...