6

8. MISCELLANEOUS INSTRUCTIONS

Remove all unused pipe plugs, apply sealant and replace. Tighten

securely. Install oil sight gauge in specified location.

Note: Each housing base has two pre-drilled holes for

doweling housing to pedestal.

9. LUBRICATION AND OPERATION

Fill pillow block with the amount of oil specified in Table 8.

Table 8 - Housing Oil Sump Capacity

Housing Size

Oil Capacity in Gallons (Quarts)

3

1-1/4 (5)

4

1-7/8 (7-1/2)

5

2-1/2 (10)

6

3-1/4 (13)

8

5-1/8 (20-1/2)

10

7-3/4 (31)

Drain, flush and refill with oil after 2 or 3 weeks of operation

and approximately every 3 months thereafter for 24 hours-a-

day service and every 6 months for 8-hours-a-day service.

Periodically check oil visually for contamination between oil

changes.

CAUTION: If heaters are used, they must be turned OFF

when oil is removed from the bearing. Failure to observe this

precaution could result in equipment damage.

NOTE: Maintain oil level at center of oil sight gauge when bearing

is operating. After placing bearing into operation, remove the

inspection cover(s) and make sure the oil rings are rotating and

bringing oil into the journal. Since the satisfactory operation of

the pillow block depends almost entirely on the oil film being

maintained between the shaft and bearing liner surface, the

use of high quality oil from a reputable manufacturer cannot be

overemphasized. Use a high grade straight mineral oil with rust

and oxidation (R & O) inhibitors and antifoam agents. Oil viscosity

is determined by the equipment manufacturer and normally

specified on the construction drawing or in the operating manual,

otherwise, see Table 8. Information regarding qualities and

properties of specific oils should be referred to the lubricant

manufacturer.

Oil film temperature in liner during operation should

not exceed 180ºF. If in doubt, consult equipment

manufacturer.

Use high grade, high quality, well refined petroleum

oils of the straight mineral type, with rust and

oxidation inhibiter and antifoam agent only.

NOTE: Bearings should NOT be stored outdoors before

installation. For extended or outdoor storage, contact

equipment manufacturer for special precautions against

corrosion.

NOTE: Bearings (and shafts) allowed to set idle for extended

periods after being run MUST be protected against corrosion.

If the unit cannot be run for several minutes at least once a

week, consult equipment manufacturer for special lubrication

instructions.

9.1 Temperature

The bearing temperature will increase after start-up until its

normal operating level is reached. Some fluctuation due to

ambient temperature change is normal, but a drastic change

MUST be investigated. Normal running temperature should not

exceed 180ºF. (Check with equipment manufacturer to see if

another operating temperature has been specified.) Low ambient

and operating temperatures can be as harmful to the bearing

as high temperatures. A heater and thermoswitch is required for

such applications.

9.2 Minimum Temperature at Start-Up:

ISO 32 oil, 60ºF

ISO 68 oil, 85ºF

ISO 100 oil, 100ºF

9.3 Vibration:

Any significant vibration or imbalance MUST be corrected. Check

with equipment manufacturer for acceptable conditions.

9.4 Options Available:

•

Heater and Thermoswitch:

WARNING: When installing heater and thermoswitch,

follow directions and safety procedures recommended

by the manufacturer. Install wiring in accordance with

the National Electrical Code and local codes. Failure to

follow these precautions could result in bodily injury.

•

Vibration Detector Kit

Содержание SLEEVOIL RXT

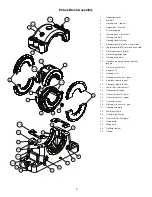

Страница 9: ...9 Oil Ring Assembly 22A 22B 22C...

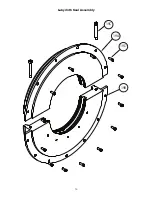

Страница 10: ...10 Labyrinth Seal Assembly 19C 19A 19D 19B...

Страница 11: ...11 Shim Collector Oil Leaf Oil Dam...