6

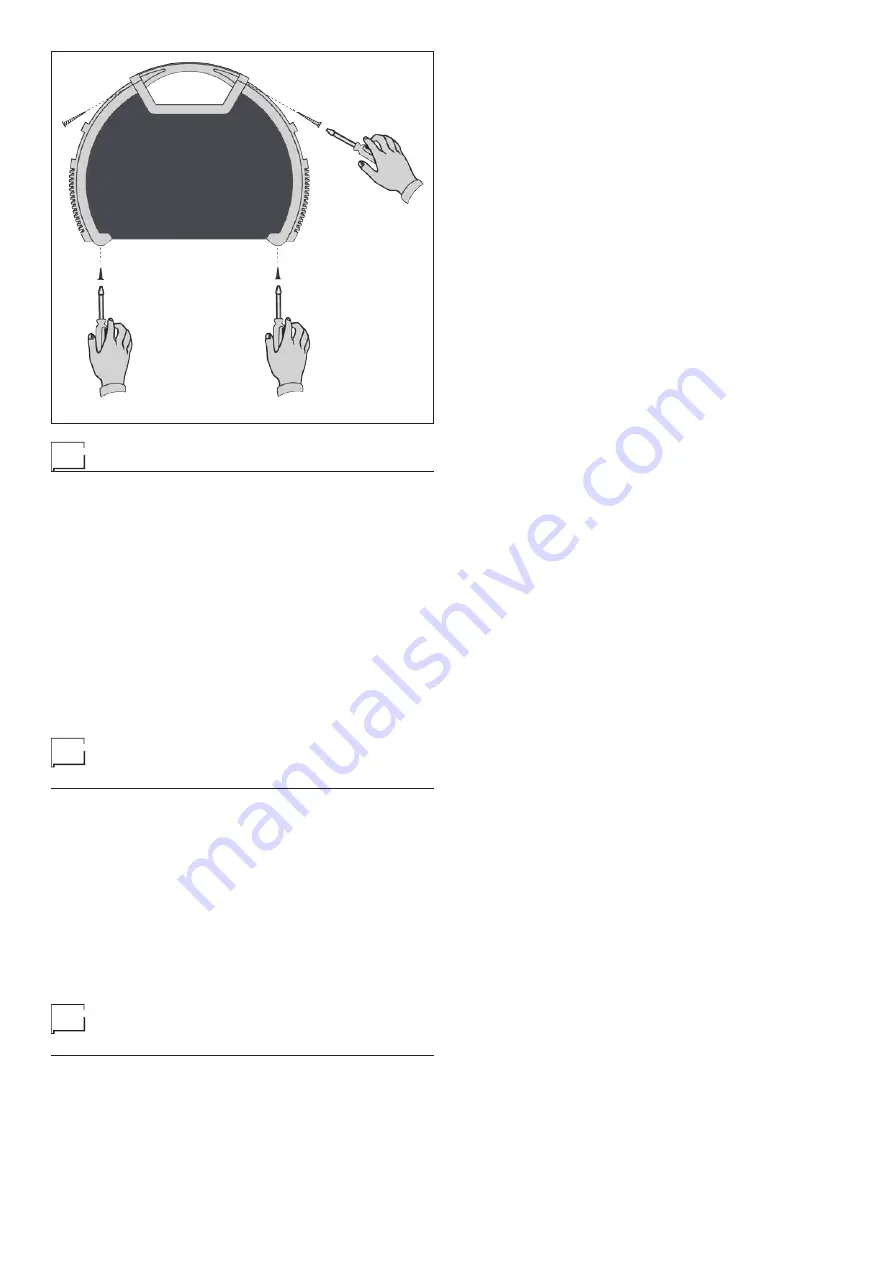

FIG. E

Maintenance

WARNING: Before carrying out any inspection of the inside of the

generator, disconnect the system from the supply.

SPARE PARTS

Original spare parts have been specially designed for our equip-

ment. The use of non-original spare parts may cause variations in

performance or reduce the foreseen level of safety. We decline all

responsibility for the use of non-original spare parts.

GENERATOR

As these systems are completely static, proceed as follow:

•

Periodic removal of accumulated dirt and dust from the inside

of the generator, using compressed air. Do not aim the air jet

directly onto the electrical components, in order to avoid dam-

aging them.

•

Make periodical inspections in order to individuate worn cables

or loose connections that are the cause of overheating.

The pointing out of any difficulties

and their elimination

The supply line is attributed with the cause of the most common

difficulties. In the case of breakdown, proceed as follows:

1) Check the value of the supply voltage.

2) Check that the power cable is perfectly connected to the plug

and the supply switch.

3) Check that the power fuses are not burned out or loose.

4) Check whether the following are defective:

•

The switch that supplies the machine.

•

The plug socket in the wall.

•

The generator switch.

NOTE: Given the required technical skills necessary for the repair

of the generator, in case of breakdown we advise you to contact

skilled personnel or our technical service department.

Procedure for welder assembly

and disassembly

Proceed as follows (Fig. E):

•

Unscrew the 4 screws holding the front and back panels.

•

Unscrew the 2 screws holding the handle.

•

Proceed the other way round to re-assemble the welder.