17

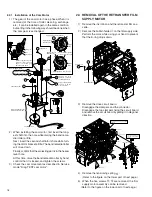

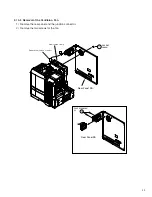

CAUTIONS FOR INSTALLATION AND

CLEANING OF BOTH ROLLERS

1) The oil bearing

%

is on the tip of the roller assembly.

Do not forget it at the time of installation and re-

moval.

2) When installing a new roller, take care that it will not

hit the bracket.

3) AC 100 V is impressed to this heater. Use sufficient

care for the wire processing.

4) Do not turn the roller by hand. The thermistor may

become damaged when the roller is turned by hand.

Accordingly, when a roller is to be turned for

cleaning etc., do the turning while the bracket

on which the thermistor is installed has been

raised a little.

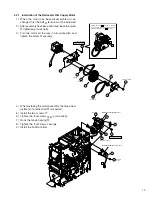

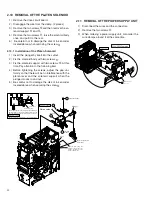

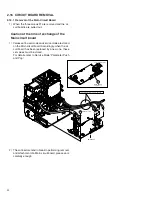

2.2 REMOVAL OF THE CAM MOTOR

1) Remove the two screws A.

Please use a long screwdriver for the lower screw.

If the power supply unit is in the way, raise it once

and use the gap underneath to perform the work.

2) Remove the screw B from front side.

Refer to section 2.9 to remove the front panel.

3) Insert the screwdriver to the hole fixing the card cool-

ing fan, and remove another screw B.

(Refer to section 2.14.3)

4) Disconnect the flat wire and the other cables.

5) Raise the bend remedial roller and pull out the mo-

tor, taking care that the motor bracket will not hit

circuit boards etc.

Screw A

Screw B

(Front side)

5

(TSS0189)

3

(TSS0182)

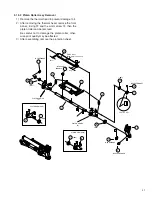

15

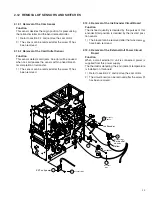

Clamp

(T2,H2)

H2

P4

17

17

T1

T2

Clamp

1

15

(TSS0181)

Pass the wires

behind the lever

(-010)

(-010)

17

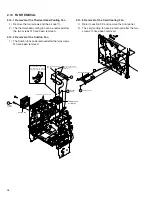

KJJ46271

-003x2

KJJ46271-003

KJJ46271-003

KJJ46271

-003x2

18

QYSPSPD

4008N

H1

T1

T2

12

Clamp

(P4)

F1

Clamp

(F1)

(FD M.MOTOR ASY)

A

B

Cam motor

Screw A

Retransfer roller

Bend remedial roller

Bearing

Thermistor bracket

screw B

17

KJJ46271

-003x2