58

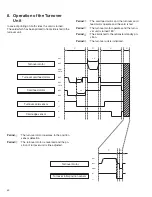

Printing defect

Cause

Countermeasure

Characters or photos ap-

pear as double images.

The ink ribbon feed system

is not constant.

1) Use the off-line test of service mode to print registration

patterns.

Confirm that the horizontal and vertical lines are within

two dots.

2) Check the take-up condition of ink ribbon and retransfer

film.

If the take-up is not uniform, check the condition of the

shaft of the ink cassette.

3) Check that ink ribbon and retransfer film are set correctly

when they are installed in the cassette.

For the retransfer film, check that the film is in the guide.

4) Check that the platen solenoid is pulled completely.

5) Check the belt tension and the screw tighteness of the

drive pully on the retransfer film supply motor.

Defective registration

Some part is not trans-

ferred correctly

(remains on the film side).

1) The card is dirty.

2) The use environment

temperature is low.

3) The card material is not

suitable.

1) Check that the card surface has not been touched with

bare hands.

2) Use the unit at a higher use environment temperature.

3) Raise the temperature setting for the retransfer roller.

4) Lower the retransfer speed.

5) Wipe the card surface with alcohol.

6) In case of small retransfer defects, check for dirt and dust.

* Cleaning roller

* Fan and filter

(Retransfer defect)

There are white lines in the

printing result or the print-

ing is thin.

Defective thermal head.

1) Clean the thermal head.

2) When perfectly white lines occur, there are some broken

heater element and the head must be exchanged.

3) When the same pattern is printed continuously, only those

lines become thin.