3 - 5

PL-6900 Series User Manual

Installing Optional Units and Expansion Boards

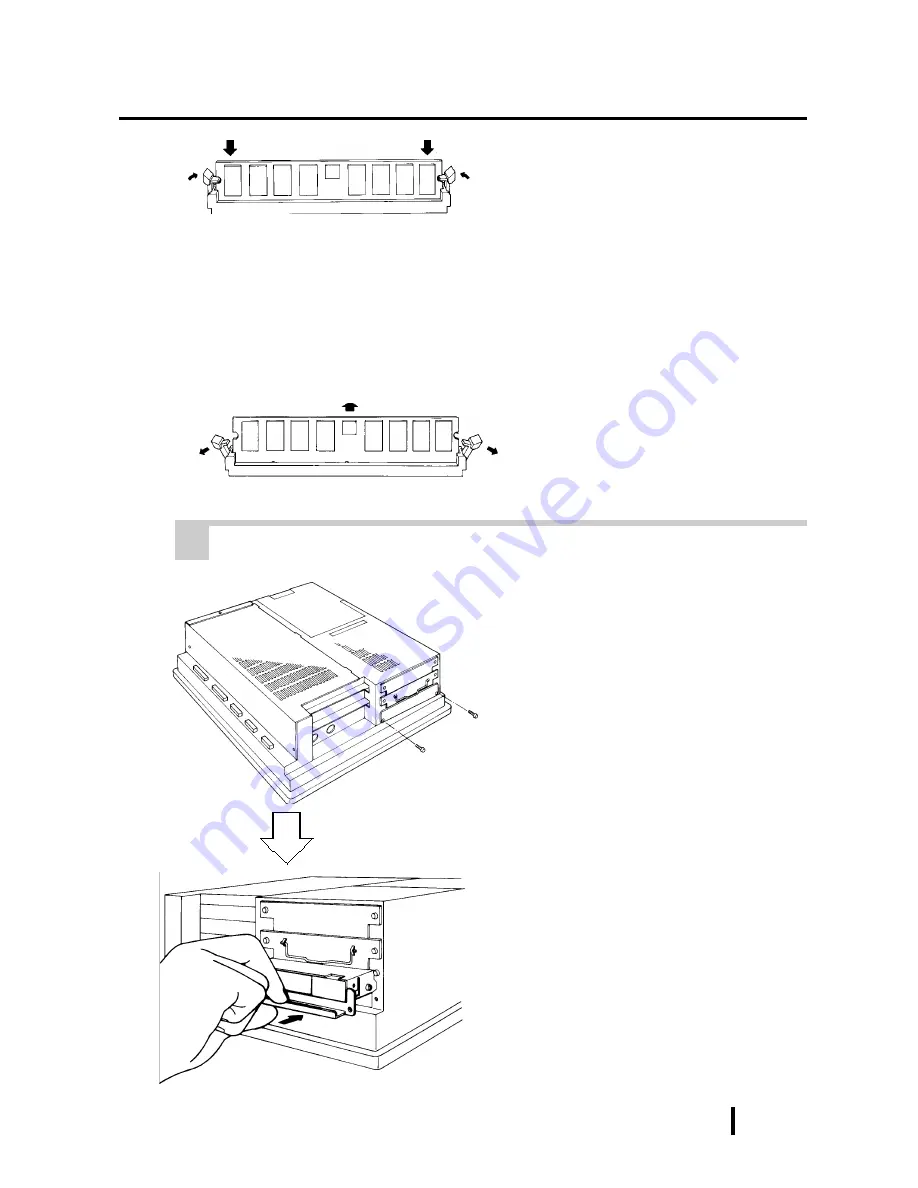

5) Push the DIM module down until

the side stoppers lock.

6) Replace the rear maintenance

cover and the half cover and secure

them in place with the attachment

screws.

To Remove the DIM Module

When removing the module from the socket, press down on the socket’s ejector

tabs to release the module.

3 Installing the FDD Unit (PL-FD200)

1) Remove the two(2) attachment

screws from the lowermost Expan-

sion Slot Cover, and remove the

cover.

2) Insert the FDD unit so that its guide

grooves fit the chassis guide ways.

Push the unit in until its rear con-

nector is connected securely.

3) Fix the unit in place with its two(2)

attachment screws.

(PL-6901T)

Содержание Pro-Face PL-6900 Series

Страница 17: ...xvi Preface PL 6900 Series User Manual MEMO ...

Страница 23: ...1 6 PL 6900 Series User Manual Overview MEMO ...

Страница 51: ...3 14 PL 6900 Series User Manual Installing Optional Units and Expansion Boards MEMO ...

Страница 61: ...4 10 PL 6900 Series User Manual Installation and Wiring MEMO ...

Страница 81: ...6 4 PL 6900 Series User Manual OS Setup MEMO ...

Страница 91: ...7 10 PL 6900 Series User Manual Maintenance and Inspection MEMO ...

Страница 101: ...App 10 PL 6900 Series User Manual Appendix MEMO ...

Страница 105: ...Index IV PL 6900 Series User Manual ...