Page 15 Manual_Revised_V1.0

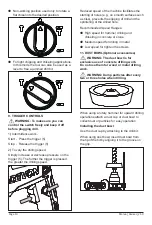

TOOL MAINTENANCE

WARNING:

Before any work on the

machine itself, pull the power plug.

1

.

Inspect bolts periodically. If the bolts loosen,

tighten them immediately, or will result in

serious accident.

2

.

Inspect tool cords periodically. The cord is

special prepared, if damaged, have repaired at

your nearest Authorized

Service

Center. This tool was used with the power cord

as a particular structure, don’t replace the

power cord without authorization, such as

replacement, please go to the Authorized

Service Center.

3

.

Keep the vents clean. Clean all parts of

the tool, clean dust periodically. To prevent

debris from entry.

4

.

Replace the carbon brush when the carbon

brush is worn out in certain length and motor

stops running. All maintenance should be

carried Out by Authorized

Service

Center.

5

.

All service MUST only be performed by

Authorized

Service Center.

ALWAYS use only

accessories

that are recommended for this tool.

6

.

Cleaning. Avoid the use of plastic cracks

caused by damage to the solvent. Use clean

cloths and mild soap to remove dirt, dust,

etc.

7

.

Avoid the tool vibration or impact, and keep

it from oil and grease.

WARNING:

Do not allow the water

enter the motor and the tool full immersed

in the ware, which will result in motor

malfunction and electric shock.

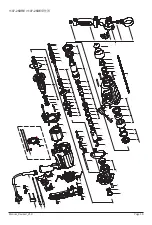

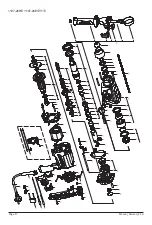

Replaceable parts list :

No Part No

Part Name

QTY

1 4810002000 Power Cord &Plug

1

2 4960256000 Carbon Brush

2

ENVIRONMENT PROTECTION

1

.

Tool, accessories and packaging should be

sorted for environment-friendly recycling.

2

.

Power tools and accessories at the end of

their service life still contain large amounts of

valuable raw materials and plastics which can

likewise be fed back into a recycling process.

3

.

Some dust created by working contains

harmful chemicals must be collected by

special garbage recycle site.

SERVICE

1

.

In case of guarantee, repair or purchase

of replacement parts, always contact the

qualified service center. And supplied with

the efficient service card and invoice.

2

.

It is without the scope of guarantee when

the tool was normal wear, overload or

improper use of damage.

Trouble Shooting

Trouble

Possible cause

Possible solution

1. Motor stops running

1. Unconnected to power source

1. Connect to power source

2. Plugs not fully connect

2. Check all plugs

3. Switch out of work

3. Replace or repair the switch

4. Brushes not touch the commutator 4. Replace the brush with a new one

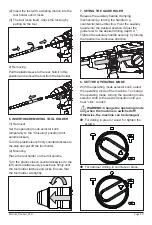

2. Drill bit doesn’t rotate. 1. Operating mode selector knob not

engaged.

1. After rotation has stopped, move

the operating mode selector knob

until it engages.

3. No hammering action

and the tool wobbles.

1. The tools is too cold

1. Allow tool to reach the minimum

operating temperature

2. Operating mode selector knob set

to rotary drilling

2. Set operating mode selector knob

to hammer drilling

4. Tool doesn’t produce

full power

1. Control switch is not pressed fully 1. Press the control switch as far as

it will go

Содержание 1107-26DE

Страница 1: ...PROFESSIONAL TOOLS GB Rotary Hammer 1107 26E 1107 26RE 1107 26DE 1107 26DRE...

Страница 3: ...Manual_Revised_V1 0 Page 2 1 1 2 3 2 1 2 3 4 5 6 RCD RCD 3 1 2 3 4 5 6 7 4 1 2 3 4 5 6 7 5...

Страница 5: ...Manual_Revised_V1 0 Page 4 5 SDS plus SDS plus 1 1 2 3 2 6 1 2 7 SDS plus 8...

Страница 6: ...Page 5 Manual_Revised_V1 0 9 10 1 2...

Страница 7: ...Manual_Revised_V1 0 Page 6 11 2 3 1 SDS plus SDS plus SDS plus 2 SDS plus SDS plus 3...

Страница 23: ...Manual_Revised_V1 0 Page 22...

Страница 24: ...Page 23 Manual_Revised_V1 0...

Страница 25: ...Manual_Revised_V1 0 Page 24...

Страница 26: ...Page 25 Manual_Revised_V1 0...

Страница 27: ......