Page 11 Manual_Revised_V1.0

and arms.

10

Use suitable detectors to find hidden electric

cables or gas and water pipes.

11

Sawdust and splinters must not be removed

while the machine is running.

12

Do not pierce the motor housing as this

could damage the double insulation

13

Ensure that ventilation openings are kept

clear when working in dusty conditions.

14

Do not operate the tool for long time, or the

quiver of the machine will hurt hands or arms.

WARNING

: Some dust created by

power Cutting contains chemicals

known to cause cancer, birth defects or other

reproductive harm. Some examples of these

chemicals are:

■ lead from lead-based paints

■ Arsenics and chromium from chemically

reacted lumber.

Your risk from these exposures varies,

depending on how often you do this type

of work. To reduce your exposure to these

chemicals: work in a well ventilated area, and

work with approved safety equipment.

STANDERD ACCESSORIES

●

Guide ruler: a set

●

Auxiliary handle: a set

Be sure to check the accessories as it is

subject to change by areas and models.

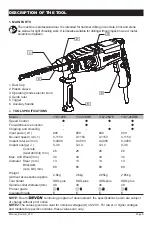

OPERATION

1 POWER SUPPLY

The power tool supply must match the

nameplate date.

2. AUTOMATIC SAFETY CLUTCH.

Protects the operator and machine from the

high reverse torque, which develops if the tool

jams all of a sudden.

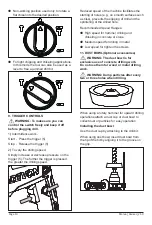

3. INSTALLING THE AUXILIARY HANDLE

Unplug the tool from the mains socket, firstly.

Release the auxiliary handle clamping band

by turning the handle in a counter-clockwise

direction. Then fit the handle band over the chuck

and onto the cylindrical section at the front end of

the tool. Pivot the auxiliary handle into the desired

position. Finally, tighten the handle securely to

prevent inadvertent movement.

WARNING:

Use the auxiliary handle

supplied. Missed operation will cause bodily

harm.

4. SELECTION OF TOOLS

For hammer drilling, SDS-plus tools are

necessary that are inserted into the SDS

drill chuck of the machine.

For drilling in steel or wood, tools without

SDS-plus (e.g., drills with cylindrical shafts)

are used. For these tools, a special drill

chuck is required (see APPLICATIONS).

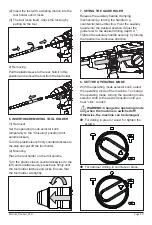

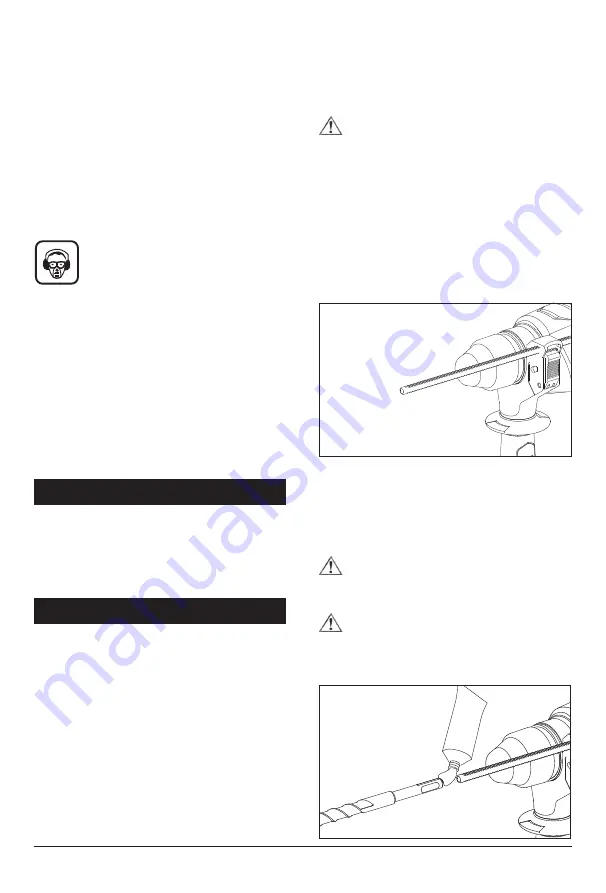

5. INSERTING/REMOVING SDS-PLUS TOOL

The SDS-plus tool is designed to be freely

movable. This causes eccentricity when the

machine is not loaded. However the drill

automatically centers itself during operation.

This does not affect drilling precision.

WARNING:

Take care when changing

tools that the dust cap is not damaged.

1

)

Inserting:

WARNING:

Grease the shank end of the

tool regularly.

(1

)

Clean the tool before inserting and lightly

grease the insertion end.

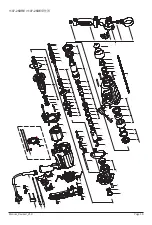

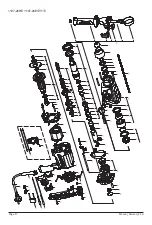

Содержание 1107-26DE

Страница 1: ...PROFESSIONAL TOOLS GB Rotary Hammer 1107 26E 1107 26RE 1107 26DE 1107 26DRE...

Страница 3: ...Manual_Revised_V1 0 Page 2 1 1 2 3 2 1 2 3 4 5 6 RCD RCD 3 1 2 3 4 5 6 7 4 1 2 3 4 5 6 7 5...

Страница 5: ...Manual_Revised_V1 0 Page 4 5 SDS plus SDS plus 1 1 2 3 2 6 1 2 7 SDS plus 8...

Страница 6: ...Page 5 Manual_Revised_V1 0 9 10 1 2...

Страница 7: ...Manual_Revised_V1 0 Page 6 11 2 3 1 SDS plus SDS plus SDS plus 2 SDS plus SDS plus 3...

Страница 23: ...Manual_Revised_V1 0 Page 22...

Страница 24: ...Page 23 Manual_Revised_V1 0...

Страница 25: ...Manual_Revised_V1 0 Page 24...

Страница 26: ...Page 25 Manual_Revised_V1 0...

Страница 27: ......