TB20061

Page 13

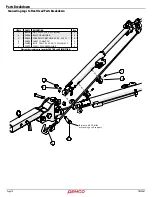

8

9

6

22

3

4

7

11

13

15

12

2

17

5

21

18

20

16

1

19

14

10

PART #

Qty DESCRIPTION

TB21039

2

Excalibar 3 Decal

TB21038

1

User Instruction Decal

TB21040

1

Warning Do Not Exceed Weight Limits &

Manufacturers Patent / Hitch Rating Decal

Please order replacement parts by PART NO. and DESCRIPTION.

DECALS

Before Towing, perform a tow bar safety check, look

for any loose fasteners, condition of safety cables,

excessive movement in connecting leg shaft when

the shaft is extended and locked. If any excessive

movement or loose fasteners are found, the tow

bar will need to be serviced before towing.

If tow bar needs servicing, please bring it to an au-

thorized dealer or send it to Demco.

Parts Breakdown

Connecting Leg Parts Breakdown

ITEM #

PART #

DESCRIPTION

Qty

1

00182

HAIR PIN, .120 WIRE X 2.375

1

2

02178

NUT, .50NC LOCK, NY. INSERT

2

3

02397

LYNCH PIN

2

4

03805

WIRE SUPPORT ROD

1

5

03809

CLEVIS SPACER WASHER

4

6

03878

ATTACHING PIN

2

7

07223

ROLL PIN, .156 X .75

1

8

13176

TRIGGER HANDLE

2

9

13179

COMPRESSION SPRING

2

10

13227

PLASTIC BUSHING, .50 ID X .75 LG

2

11

13249

CLEVIS GROOVED PIN, .313 X 1.25, SS

4

12

13250

RETAINING RING F/ .313 SHAFT

4

13

13431

STORAGE PIN

2

14

13432

RETAINING E-CLIP, SS F/ .25 SHAFT

2

15

13527

CONNECTING CLEVIS F/INDEP.ARM TB

2

16

13561

SCREW, BUTTON SOCKET HD, .313NC X .5 SS

16

17

13859

LATCH SEAR

2

18

15352

BOLT .50NC X 2.75 W/1.75 SHANK

2

19

15712

CONNECTING LEG SHAFT

2

20

16702

CONNECTING LEG TUBE, LEFT

1

21

16703

CONNECTING LEG TUBE, RIGHT

1

22

16704

FRONT ADAPTOR

2

Please order replacement parts by PART NO. and DESCRIPTION.

Содержание Excalibar 3

Страница 1: ...TB20061 Rev 2 09 19 SELF ALIGNING TOW BAR Excalibar 3...

Страница 19: ...TB20061 Page 19...

Страница 20: ......