CANopen Communication Module DVPCOPM-SL

3.3

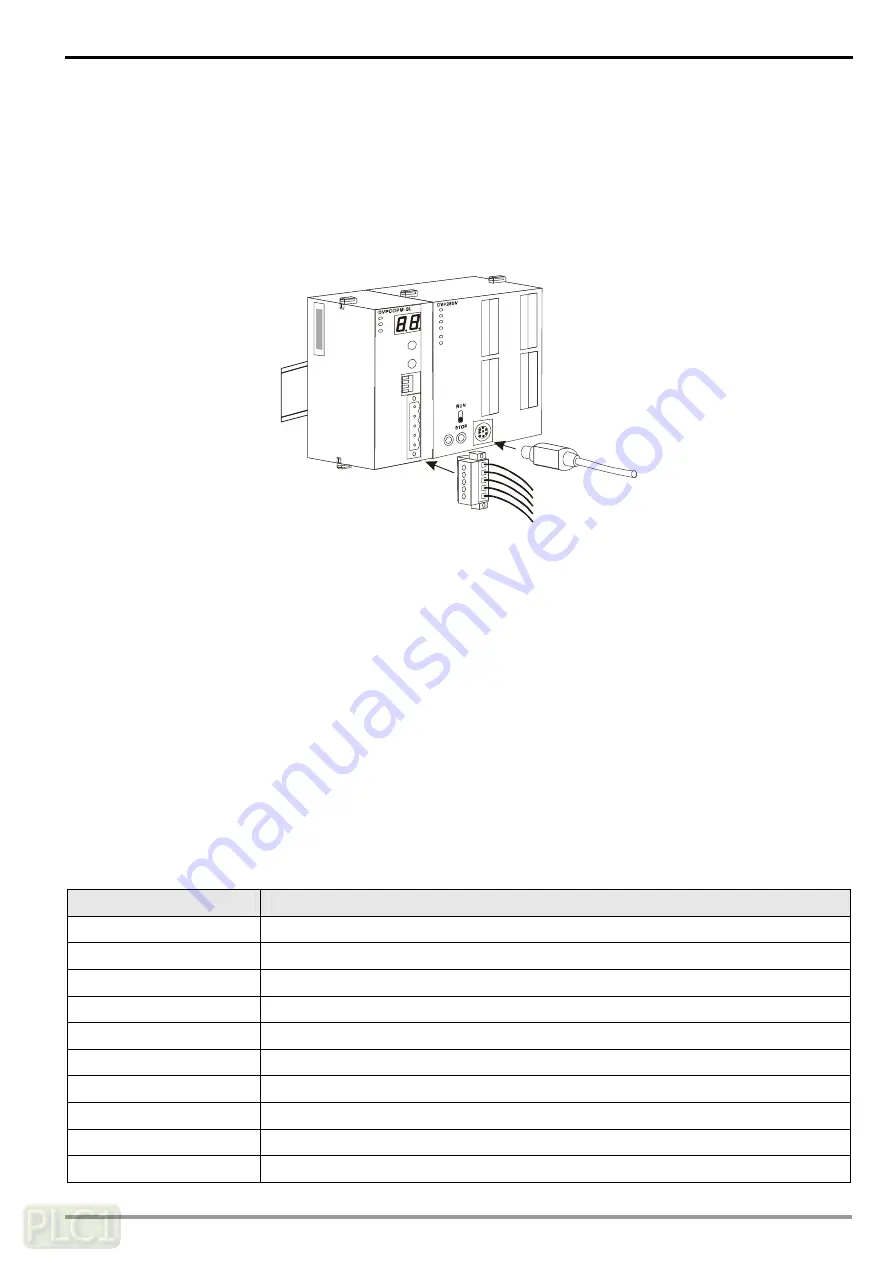

Connecting to CANopen Connection Port

Please wire following the PIN definition of the connection port.

There are two communication interfaces on DVP-SV to communicate with the PC. COM1 is the standard RS-232

interface, and COM2 RS-485. Both interfaces comply with Modbus protocol. The PC communicates directly to PLC

through COM1.

We recommend you also apply Delta’s power module in the connection.

RS-232

4

Constructing CANopen Network

In this section, we will introduce how to construct a complete CANopen network by using DVPCOPM-SL and other

slaves.

Before constructing a network, you have to first know clearly what the network is for and start a preliminary planning for

the data to be exchanged. The plan shall include the slaves to be used, type of transmission and the data to be

exchanged, total length of data to be exchanged, requirement on the response time for data exchange, and so on. The

information will decide whether the network you construct is a reasonable one, or if it satisfies your needs, and even

affect the later-on network sustainability and flexibility of network capacity upgrade.

In the example below, we will illustrate how to control RUN/STOP and speed of a Delta ASD-B servo drive by a Delta

digital I/O module DVP-08ST.

4.1

How to Construct a CANopen Network

Equipment and software required:

Equipment & software

Function

DVP-PS02

24V power supply module, supplying CANopen network.

DVP-PS01

24V power supply module, supplying DVP-12SA and remote I/O DVP-08ST.

DVP-28SV

DVP-SV PLC CPU

DVPCOPM-SL CANopen

master

DVP-12SA

DVP-SA PLC CPU

DVP-08ST

Digital I/O module

IFD9503

CANopen bus adapter

ASD-B

Delta B series servo drive

WPLSoft

DVP series PLC programming software

Delta CANopen Builder

CANopen configuration software for DVPCOM-SL master

DVP-PLC Operation Manual

11