C1000 Series Service & Maintenance Manual

Service and Repair

SECTION IV

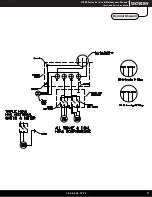

PNEUMATIC

WARNING

: HIGH SYSTEM PRESSURES MAY CAUSE SERIOUS INJURY.

ALWAYS DEPRESSURIZE THE ENTIRE SYSTEM BEFORE ATTEMPTING TO SERVICE PNEUMATIC COMPONENTS.

1.

Replacing the check valves.

If a check valve failure occurs, the symptom will be air escaping through one of the compressor

heads with the compressor NOT running. To replace a defective check valve, unscrew “counterclockwise” the air discharge hose

fi

tting

from the appropriate compressor head. Once the air discharge hose is disconnected from the compressor head, the check valve,

along with the discharge hose, may be removed from the discharge manifold by unscrewing the check valve ”counterclockwise”, and

replaced with a new check valve. Reverse this process to reassemble the check valve / discharge hose assembly.

2.

Replacing the Differential Filter Indicator.

If the differential indicator becomes stuck in either the red OR green

indicating position, the indicator needs replacement. Replace the differential

fi

lter indicator by unscrewing the entire assembly

“counterclockwise” with a 15/16” - 6 point / box end wrench. Install the new indicator in the reverse order.

3.

Automatic Filter Float Drain.

Unscrew the coalescing

fi

lter bowl from the

fi

lter head. Using a 9/16 wrench, unscrew the

retaining nut on the bottom of the

fi

lter bowl. With the retaining nut removed, the automatic

fl

oat drain will be removed from the

fi

lter bowl. Replace in the reverse order.

4.

Replacing Desiccant Chamber.

To replace the desiccant chamber, remove the rigid stainless steel tubing from the dryer

bypass valve at the compression

fi

tting, located at the dryer bypass valve. Remove the top plumbing manifold assembly from the top

of the desiccant chamber, by turning counterclockwise. Remove the electrical cord from the dryer purge valve by removing the Philips

head retaining screw, and pulling the cable away from the valve timer block. Next, remove the

fl

exible discharge hose from the

discharge side of the coalescing

fi

lter, and then unscrew the bottom manifold assembly from the bottom of the desiccant chamber.

Replace the desiccant chamber and reassemble in the reverse order.

1.800.624.2793

15

Unpacking

Electrical