15

3.0 INSTALLATION

IMPORTANT:

The Flexiguard

®

Boxed-Frame Rail Fall Arrest System must be assembled by a Qualified Person and the installation

must be certified by a Qualified Person as: meeting the criteria for a Certified Anchorage, or capable of supporting the potential forces

that could be encountered during a fall.

1

IMPORTANT:

Do not alter or intentionally misuse this equipment. Consult 3M when installing or using this equipment in

combination with components or subsystems other than those described in this manual. Some subsystems and component combinations

may interfere with the operation of this equipment.

3.1 PLANNING:

Plan your fall protection system prior to installation of the Flexiguard Boxed-Frame Fall Arrest System (FAS).

Account for all factors that may affect your safety before, during, and after a fall. Consider all requirements, limitations,

and specifications defined in Section 2 and Table 1.

3.2

ASSEMBLING THE BOX FRAME:

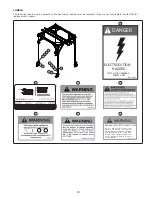

Figure 8A illustrates installation of the Box Frame:

1. Insert the setup bar (B) into the bottom of the corner assembly (A) in each corner of system.

2. Fasten cross bars (C&D) to all corner assemblies (A) using 1/2 inch hardware. Torque hardware to 60 ft*lbs (81

N*m).

3.

Fasten top gussets (G1) to the cross bars (C&D) using 1/2 inch hardware. Torque hardware to 60 ft*lbs (81 N*m).

4.

Fasten the rail bracket (F) to cross bar (C) using 1/2 inch hardware. Space the rail brackets (F) 36” [914 mm] a part

for dual rail systems and center single rails. Torque hardware to 60 ft*lbs (81 N*m).

5.

Fasten the rail assembly (G) to the rail bracket (F) using the 1/2 inch hardware. Torque hardware to 60 ft*lbs (81

N*m).

6. Place the two ears from the leg assembly (H) between the two ears on the corner assembly (A) and fasten using the

5/8 inch hardware. Verify the bolt is able to rotate.

7. Attach lifting straps to the (4x) corners of the frame assembly.

8.

Using an overhead crane, pick from all four corners of the frame and raise slowly into place. Place padding

underneath each leg assembly to allow the legs to slide along the ground.

9. Once the system is fully raised and the legs are vertical and slightly off the ground, lower the system onto the legs

but keep system supported by overhead crane.

10. Use personnel lift to fasten the leg assembly (H) to the corner assembly (A).

11.

Install the remaining corner and side gussets (G2 and G3) and fasten using 1/2 inch hardware. Torque to 60 ft*lbs

(81 N*m).

12. Fasten the wheel assemblies to the upright using the 3/8 inch hardware. Torque to 45 ft*lbs (61 N*m).

13. If the system is adjustable in height, fasten the lifting brackets on each leg assembly above each adjustment pin and

fasten using 3/8 inch hardware. Torque hardware to 45 ft*lbs (61 N*m). See Figure 9.

14.

Install the cross tube between each lifting bracket using the two pins provided.

3.3

ASSEMBLING THE 8530427 BOX FRAME:

Figure 8B illustrates installation of the 8530427 Box Frame:

1. Insert the setup bar (B) into the bottom of the corner assembly (A) in each corner of system.

2. Fasten cross bar (C) to the plate of the corner assembly (A) using the 3/4 inch hardware. Fasten cross section (D)

between the two plates of the corner assembly (A) using the 3/4 inch hardware. Torque hardware to 130 ft*lbs (176

N-m).

3.

Fasten top gussets (G1) to the cross bars (C) using 1/2 inch hardware. Torque hardware to 60 ft*lbs (81 N*m).

4.

Fasten the (4x) rail bracket (F) around the bottom tube of cross bar (C) using 1/2 inch hardware. Space the brackets

36” [914 mm] a part on both sides of system centered on the cross bars (C). Torque hardware to 60 ft*lbs (81 N*m).

5.

Fasten the rail assembly (G) to the rail bracket (F) using the 1/2 inch hardware. Torque hardware to 60 ft*lbs (81

N*m).

6. Place the two ears from the leg assembly (H) between the two ears on the corner assembly (A) and fasten using the

5/8 inch hardware. Verify the bolt is able to rotate.

7. Attach lifting straps to each corner of the system.

8.

Using an overhead crane, pick from all four corners of the frame and raise slowly into place. Place padding

underneath each leg assembly to allow the legs to slide along the ground.

9. Once the system is fully raised and the legs are vertical and slightly off the ground, lower the system onto the legs

but keep system supported by overhead crane.

10. Use personnel lift to fasten the leg assembly (H) to the corner assembly (A) using the 3/4 inch hardware provided.

11.

Install the remaining corner and side gussets (G2 & G3) and fasten using 1/2 inch hardware. Torque to 60 ft*lbs (81

N-m).

12. Fasten the wheel assemblies to the upright using the 3/8 inch hardware. Torque to 45 ft*lbs (61 N*m).

Towing:

See instruction 5908365 for the Tow Bar Kit.

1 Qualified Person:

A person with a recognized degree of professional certificate and with extensive knowledge, training, and experience in the fall protection

and rescue field who is capable of designing, analyzing, evaluating, and specifying fall protections and rescue systems to the extent required by OSHA and other

applicable standards

Содержание OSHA 1926.502

Страница 2: ...2 2 A B H C B D E G F...

Страница 5: ...5 8 A H G2 G3...

Страница 6: ...6 8 A B 36 914 mm D D C G1 G1 G1 G1 C G F D C A H A 8B...

Страница 7: ...7 8 G3 G2...

Страница 8: ...8 9 1 2 3 5 4...

Страница 9: ...9 10 1 A B C 11...

Страница 10: ...10 11...