Step 2: Cleaning and Lubrication of the DEUTSCH HDT-48-00 & DANIELS AF8 M22520/1-01

Carefully clean all the various components, paying special attention to the Lever Arm, Indenter

Housing, Indenters and Springs ans the various shim plates, using a solvent like rubbing alcohol

alcohol being sure to remove all old grease, and any debris or particulate. Be especially sure to

carefully clean the passages in the Indenter Housing and the cam grooves on the Lever Arm.

Compressed air is especially good for this task. You should also examine all components for wear

-- excessive wear to the Indentors or cams will result in out-of-spec crimps. These parts cannot be

repaired -- if excessively worn the, crimp tool must be replaced. However, regular cleaning and

lubrication will greatly extend the life of the crimp tool.

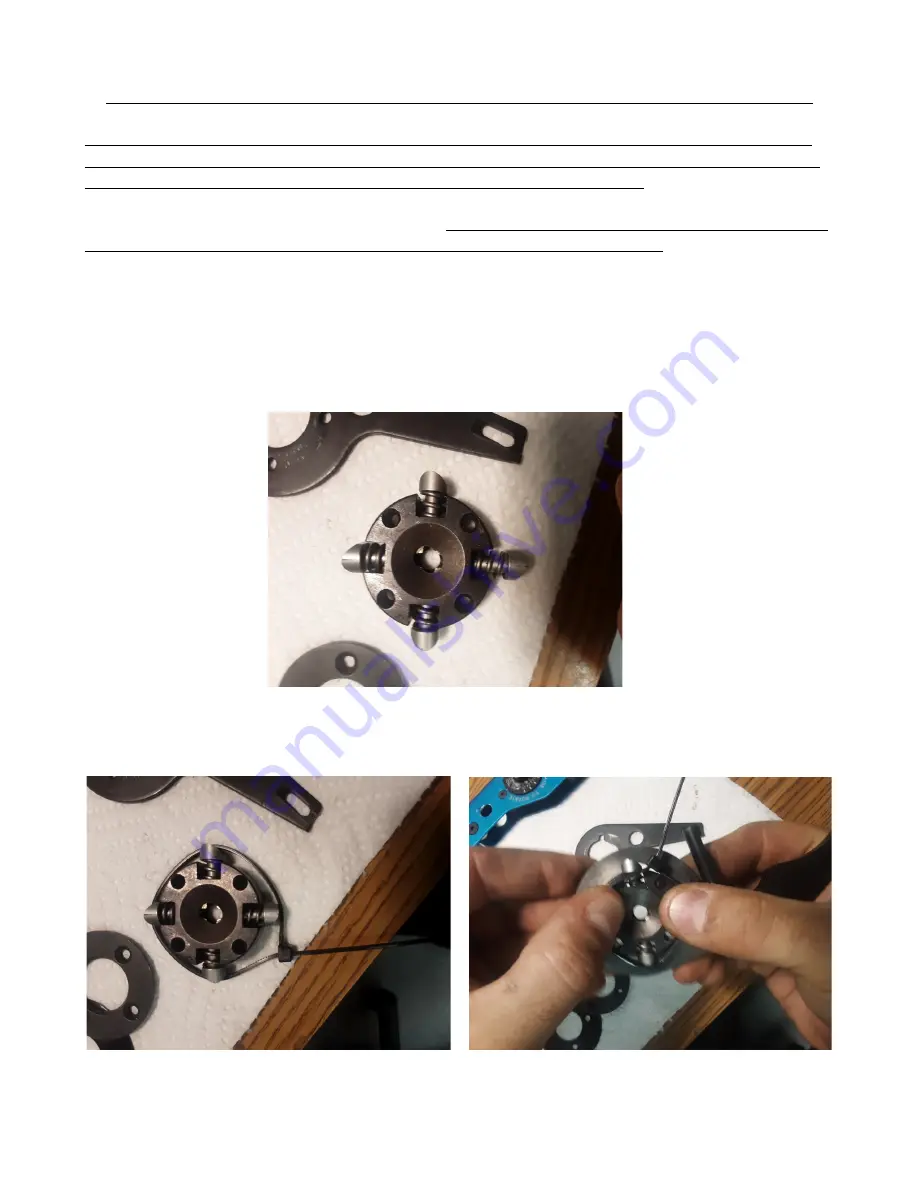

When you have finished cleaning the components, reassemble the Indenters and Springs in the

Indenter Housing, WITH CARE TO RETURN THE INDENTER CAM LOBES AND THE MACHINED

SLOT TO THE CORRECT ORIENTATION. You are now ready to reinstall the Indenter assembly in

the Lever Arm.

Reinstalling the Indenter assembly in the Lever Arm is tricky as the Indenter's Cam lobes must be

correctly oriented and the springs must all be simultaneously compressed. We have found that

the best way to accomplish this tricky operation is to compress the assembly (taking care to

preserve cam lobe orientation) with a zip tie, and then insert it into the Lever Arm compressed: