Step 3: Reassembly of the DEUTSCH HDT-48-00 or DANIELS AF8 M22520/1-01 Crimp Tool

After completing cleaning and lubrication, you are ready to Reassemble the Crimp Tool.

Reassembly of the tool is moderately difficult, and requires care and a steady hand.

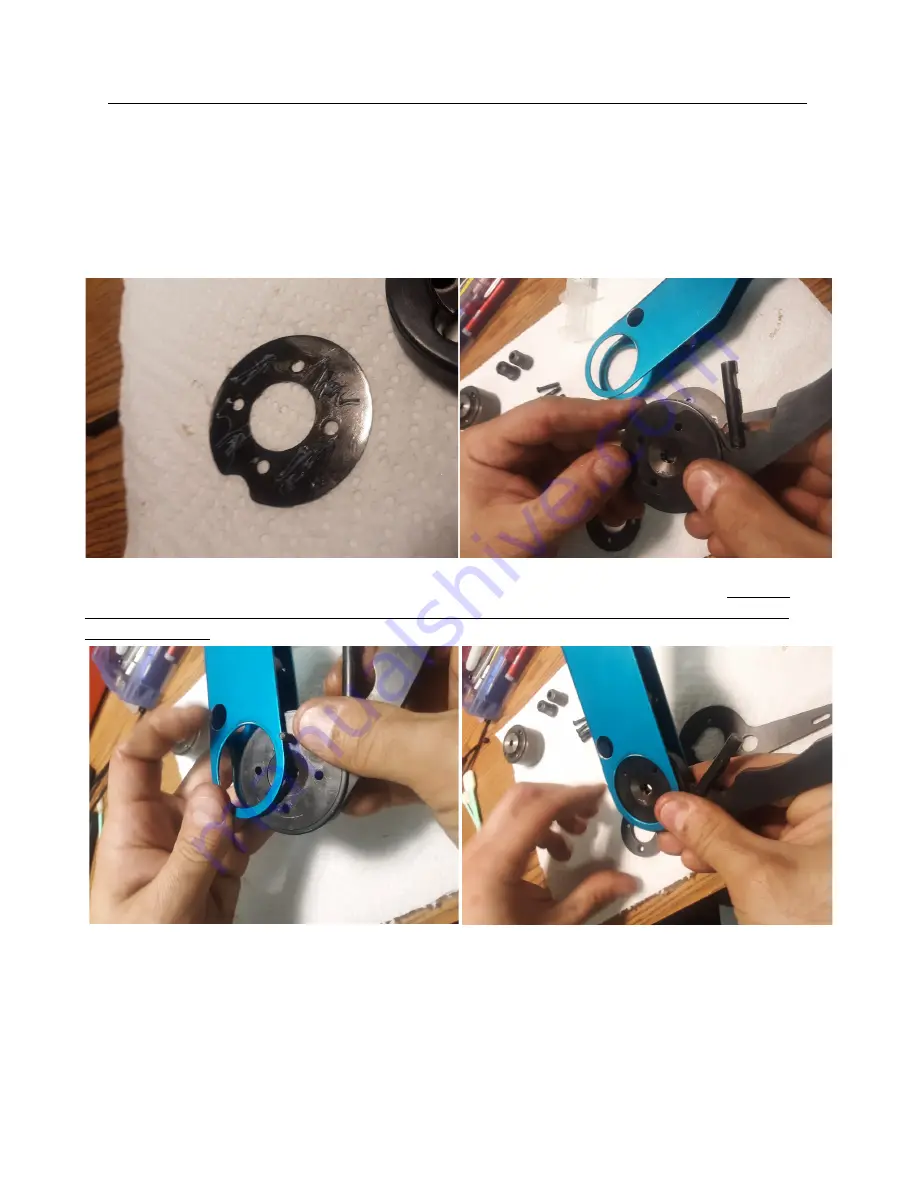

First, place the Shims back on the Lever Arm and Indenter Assembly, one on each side. Note the

orientation of the cutout on the shim which interfaces with a pin in the Crimp Tool's Body. Apply a

thin bead of Krytox Grease to the Shims on both sides -- this will aid in re-installation by making

the shim stick to the Indenter Assembly, and also will help lubricate the tool in use:

Carefully keeping the shims aligned, insert the assembly into the Crimp Tool's Body. You can

temporarily insert the Torx Bolts BACKWARDS through the assembly to help keep it aligned

during insertion:

After you have the Arm/Indenter assembly in the Tool body, rotate the arm and insert the Ratchet

Arm which is attached to the Lever Arm into the Ratchet Pawl assembly attached to the Tool Body.