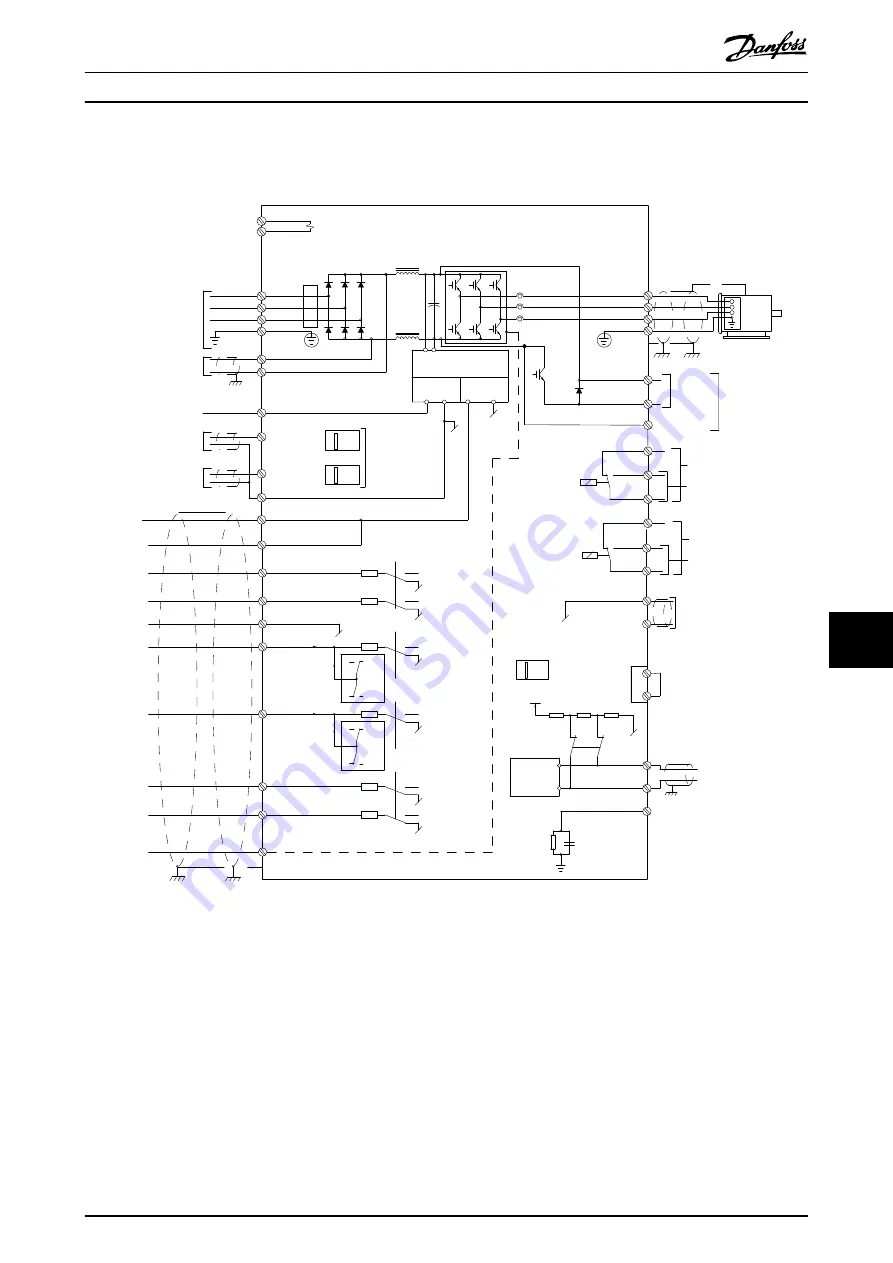

10.2 Wiring Schematic

130BF111.11

230 V AC

50/60 Hz

TB5

R1

Regen +

Regen - 83

Regen (optional)

1

2

Brake temperature

(NC)

Space heater (optional)

91 (L1)

92 (L2)

93 (L3)

PE

88 (-)

89 (+)

50 (+10 V OUT)

53 (A IN)

54 (A IN)

55 (COM A IN)

0/4-20 mA

12 (+24 V OUT)

13 (+24 V OUT)

18 (D IN)

20 (COM D IN)

15 mA

200 mA

(U) 96

(V) 97

(W) 98

(PE) 99

(COM A OUT) 39

(A OUT) 42

0/4-20 mA

03

+10 V DC

-10 V DC - +10 V DC

0/4-20 mA

24 V DC

02

01

05

04

06

240 V AC, 2A

24 V (NPN)

0 V (PNP)

0 V (PNP)

24 V (NPN)

19 (D IN)

24 V (NPN)

0 V (PNP)

27

24V

0V

(D IN/OUT)

0 V (PNP)

24 V (NPN)

(D IN/OUT)

0V

24V

29

24 V (NPN)

0 V (PNP)

0 V (PNP)

24 V (NPN)

33 (D IN)

32 (D IN)

1

2

ON

A53 U-I (S201)

ON

2

1

A54 U-I (S202)

ON=0-20 mA

OFF=0-10 V

95

400 V AC, 2A

P 5-00

(R+) 82

(R-) 81

37 (D IN)

1)

+ -

+

-

(P RS485) 68

(N RS485) 69

(COM RS485) 61

0V

5V

S801

RS485

RS485

2

1

ON

S801/Bus Term.

OFF-ON

3-phase

power

input

Load share

Switch mode

power supply

Motor

Analog output

interface

Relay1

Relay2

ON=Terminated

OFF=Open

Brake

resistor

(NPN) = Sink

(PNP) = Source

=

=

=

240 V AC, 2A

400 V AC, 2A

-10 V DC - +10 V DC

10 V DC

(optional)

(optional)

Illustration 10.1 Basic Wiring Schematic

A=Analog, D=Digital

1) Terminal 37 (optional) is used for Safe Torque Off. For Safe Torque Off installation instructions, refer to the VLT

®

FC Series - Safe

Torque Off Operating Guide.

Electrical Installation Con...

Design Guide

MG38C202

Danfoss A/S © 01/2018 All rights reserved.

145

10

10

Содержание VLT AutomationDrive FC 302

Страница 2: ......

Страница 211: ...Index Design Guide MG38C202 Danfoss A S 01 2018 All rights reserved 209...