D

GB

F

PT

I

TR

© Danfoss | Climate Solutions | 2023.07

AQ453354265896en-000201| 17

6

|

Maintenance

Since changing the shaft seal involves encroaching into

the refrigerant circuit, this is only recommended, if the seal

is losing refrigerant, or if oil is escaping in excess of the

permissible amount (see information on page 14, chapter

5.7, "Shaft seal"). Changing the shaft seal is described in the

relevant spare part kit.

Emptying the oil reservoir:

The oil reservoir can be emptied

very simple without having to dismantle the clutch and/or

belt drive. It is recommended that this is done at the same

time as the air-conditioning maintenance and motor service.

To proceed, detach the oil hose from the bracket, remove the

sealing plug and drain the oil into a collecting vessel. After

emptying, reseal the oil hose and clamp it into the bracket.

Dispose of the used oil in accordance with national

regulations.

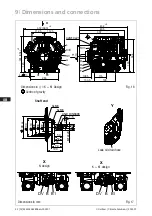

6.3 Shaft seal, emptying the oil reservoir

Fig. 15

Emptying the shaft seal oil reservoir:

As required depending on use, but at the latest after 1 year

or approx. 1,400 operating hours

Where requirements are higher during use

(frequent operation at the limits of application, or

in hotlands with over +40 °C ambient temperature, or in the case of deep freezing), the following

requirements must be observed:

• Initial oil change during the first maintenance of the vehicle (at the latest after one year)

• Then an oil change after every 2,000 operating hours, at the latest however after two years. Also

clean the oil filter.

Preventive maintenance

The above requirements for higher use applications also apply in the case of preventive

maintenance. The shaft seal must also be changed after 3 years.

Regular inspections (at least annually):

Checks to be carried out on oil level in the oil sight

glass, oil fill level of the shaft seal in the oil drain hose, absence of leaks in the compressor, running

noise, vibrations, pressures, temperatures, and functioning of auxiliary devices such as the capacity

control.

The shaft seal is a wearing part, and its service life depends on the prevailing conditions.

Damaging effects on the shaft seal:

• Too little suction gas superheat, particularly during wet operation

• Too high or too low belt tension

• Thermal overload (operation outside the limits of application)

• Frequent cycling

• Long periods of stoppage

• Material deposits / dirt from the system

Due to these effects, the shaft seal can develop leaks, and it must then be replaced.