D

GB

F

PT

I

TR

© Danfoss | Climate Solutions | 2023.07

AQ453354265896en-000201| 13

4

|

Compressor assembly

Fig. 14

The M10 threads in the housing can be used for screwing on attachments and bracing the

compressor.

• Maximum load on the screw connection = 6 g-Kraft

• Maximum tightening torque of the screws = 60 Nm with minimum screw-in depth = 20 mm

and friction coefficient = µ 0,15.

• Maximum screw-in depth 25 mm.

• Usable screws up to strength class 10.9.

In case of screw-in depths less than 15 mm or lower friction coefficients than µ = 0.15, the tightening

torques and maximum load must be reduced.

INFO

If the M10 threads are used as additional bracing, installation is

overdetermined. It must be ensured that the compressor housing is not

distorted during installation. The specifications of the motor / chassis

manufacturer are mandatory

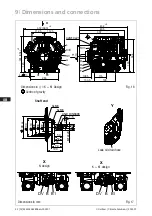

4.11 Characteristics for K1 special housing

130

72

16

5

115

21

0

Dok-ID:

F

E

D

C

A

F

E

D

C

4

1

A

B

5

6

7

8

1

2

3

4

5

6

7

8

Zeichn.-Nr. / Drawing-no. :

B

3

2

1.0851-13926.0 0b

A. Layh

Part-No.

Maßstab /

bis / up to

über / above

Freigabe / Approved

packaging for safe transportation).

in proper conditions (corrosion prevention,

The supplier has to ensure the delivery of parts

Transport).

(Korrosionsschutz, Verpackung für sicheren

in einwandfreiem Zustand angeliefert wird

Der Lieferant muss sicherstellen, dass die Ware

z

y

x

w

u

t

s

model or design.

1.0851-13918.0 0i

Ersatz für / replacement for:

DIN ISO 2768-mK-E

18.08.2021

A. Layh

Allgemeintoleranzen / General tolerances

of the grant of a patent, utility

payment of damages. All rights reserved in the event

prohibited. Offenders will be held liable for the

Dimension

Passung / Clearance

Baumustergeprüft / Type examination:

-

-

K.-Auftrag / C.-Task:

Projektleiter / Project leader:

120

400

±0.5

0.5

6

BOCK GmbH - Benzstraße 7 - 72636 Frickenhausen - Germany - www.bock.de

-

-

-

Unbemaßte Radien / Undimensioned radii:

-

Bearb. / Edited

Datum / Date

Änd.-Nr. / Mod-No.

Material (Line 2+3 alternative):

Werkstoff (Zeile 2+3 alternativ) /

Base part, Raw part:

-

-

Geprüft / Appr.

Name

Datum / Date

18.08.2021

18.08.2021

Ausgangsteil, Rohteil /

Workpiece edges

DIN ISO 13715

Erstellt / Drawn

Geprüft / Verified

J. Faßbender

S. Büttner

1/4

Oberflächenbehandlung, Härte / Treatment of surface, Hardness:

-

Werkstückkanten /

Page:

400

Benennung / Description:

±0.8

1000

30

6

-

±0.3

120

30

±0.2

Blatt /

Drawing-No.

Zeichnungs-Nr. /

/

DIN EN ISO 1302

Zust. / Rev.

Gußtoleranzen / General casting tolerances:

Gewicht / Weight: (kg)

±0.1

Indication of surface texture

Scale:

%

C - FKX50/980 K

Rz 25

Rz 160

Rz 1,6

Rz 16

Rz 63

Rz 6,3

Rz 12,5

-

-

Nein / No

13926 .0

26.07.22

16.12.22

S. Büttner

C. Polizzi

0a | K1-Ausführungen aufgenommen

0b | Betrifft Bl.3

11620

11738

A. Layh

A. Layh

K - FKX50/980 K

-

0851

1.

Kunde / Customer:

-

Weitergabe sowie Vervielfältigung dieses Dokuments,

Verwertung und Mitteilung seines Inhalts sind ver-

boten, soweit nicht ausdrücklich gestattet. Zuwider-

handlungen verpflichten zu Schadenersatz. Alle

Rechte für den Fall der Patent-, Gebrauchsmuster-

oder Geschmacksmustereintragung vorbehalten.

The reproduction, distribution and utilization of this

document as well as the communication of its

contents to others without express authorization is

Maß

Oberflächenangaben /

Teile-Nr. /

364912

nur bei K1 Ausführung

only for K1 version

13

6

130,5

166

2x

M

10

DV

B

B1

Ventilausführung K+K1-Version

valve version K+K1-version

G

L

C/E

A

A1

M

SV

33

1

(33

4)

14

5

112,5

255

+2

112,5

13

4x

372 (380)

+2

A5x9 DIN6888

8xM8

6xM8

1:5

x28

54

66

74

100

90

98

M

12

110

h8

50

148

2

40

Fahrzeugverdichter / Vehicle Compressor

Typ / type

Teile-Nr. / part-no. Typ / type

Teile-Nr. / part-no. Typ / type

Teile-Nr. / part-no.

FKX50/660 N

13875 *

FKX50/660 K

13876

FKX50/660 K1

14248

FKX50/775 N

13877 *

FKX50/775 K

13878

FKX50/775 K1

14249

FKX50/830 N

13923

FKX50/830 K

13924

FKX50/830 K1

14250

FKX50/980 N

13925 *

FKX50/980 K

13926

FKX50/980 K1

14251

* Keine Serie / No series

Anschlüsse /

Connections

FKX50

N

FKX50

K + K1

SV

Saugabsperrventil, Rohr (L)*

mm - Zoll /

mm - inch

2x35 - 1 3/8"

mit Staubschutz

verschlossen /

closed with

dust cover

Suction line valve, tube (L)*

DV

Druckabsperrventil, Rohr (L)*

mm - Zoll /

mm - inch

35 - 1 3/8"

Discharge line valve, tube (L)*

A

Anschluss Saugseite, nicht absperrbar

Zoll / inch

1/8“ NPTF

Connection suction side, not lockable

A1

Anschluss Saugseite, absperrbar

Zoll / inch

7/16“ UNF

Connection suction side, lockable

B

Anschluss Druckseite, nicht absperrbar

Zoll / inch

1/8“ NPTF

Connection discharge side, not lockable

B1

Anschluss Druckseite, absperrbar

Zoll / inch

7/16“ UNF

Connection discharge side, lockable

C

Anschluss Öldrucksicherheitsschalter OIL

Zoll / inch

1/8“ NPTF

Connection oil pressure safety switch OIL

D

Anschluss Öldrucksicherheitsschalter LP

Zoll / inch

1/8“ NPTF

Connection oil pressure safety switch LP

E

Anschluss Öldruckmanometer

Zoll / inch

1/8“ NPTF

Connection oil pressure gauge

F

Ölablass

Zoll / inch

1/4“ NPTF

Oil drain

G

Opt. Anschlussmöglichkeit Ölsumpfheizung 1)

-

-

Opt. connection oil sump heater 1)

H

Stopfen Ölfüllung

Zoll / inch

1/4“ NPTF

Oil charge plug

K

Schauglas

Zoll / inch

2 x 1 1/8 “ – 18 UNEF

Sight glass

L

Anschluss Wärmeschutzthermostat

Zoll / inch

1/8“ NPTF

Connection thermal protection thermostat

M

Ölsieb

mm

M22x1,5

Oil filter

SV1

Opt. Anschlussmöglichkeit Saugabsperrventil

-

-

Opt. connection suction line valve

(L)* = Lötanschluss / brazing connection

1) = Nur ab Werk möglich / ony possible ex factory

( ) K + K1 Ausführung

( ) K + K1 version

Massenschwerpunkt

Centre of gravity

Änderungen vorbehalten

Subject to change without notice

Maße in mm

Dimensions in mm

SV1

D

H

K

F

4xM10x21

Lecköl-Ablass Schlauch

Leak oil drain hose

357

108,5

133,5

190

405

432

+2

30

4

B1

B

DV

Ventilausführung N-Version

valve version N-version