26

User

Guide RS8GR602 © Danfoss 2016-10

AK-CT

450A

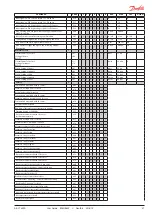

Configuration of light function

(If night blind selected, it will be synchronised with the light function)

1) Light is controlled via day/night status

2) Light is controlled via data communication and "Light remote o39"

3) Light is controlled by door contact, as defined via a DI input where the setting is

selected as either 2 or 3. When the door is opened the relay will cut in. When the

door is closed again there will be a time delay of two minutes before the light is

switched off.

4) As "2" but if there are any 15-minute network errors, the light will switch on and

the night blind will open.

5) Light controlled with local DI switch and a central signal from either data commu-

nication or a 230 V signal on DI7. Both must be on before the light is turned on.

6) Like “5”, but manual control of the night blind will also activate the light, which

means the light will switch on when the night blind is up.

o38

Light config

Activation of light relay

Here the relay can be activated, but only if a setting of 2, 5 or 6 has been defined in

o38.

o39

Light remote

Rail heat during day operation

The ON period is set as a percentage of the time

o41

Railh.ON day%

Rail heat during night operation

The ON period is set as a percentage of the time

o42

Railh.ON ngt%

Rail heat cycle

The period of time for the aggregate ON time + OFF time is set in minutes

o43

Railh. cycle

Case cleaning

The status of the function can be followed here or the function can be started

manually.

0 = Normal operation (no cleaning)

1 = Cleaning with fans operating. All other outputs are Off.

2 = Cleaning with stopped fans. All outputs are Off.

If the function is controlled by a signal at a DI-input, the relevant status can be seen

here in the menu.

o46

Case clean

Selection of application

The controller can be defined in various ways. Here you set which of the

8 applications is required. On page 13 to 16 you can see a survey of applications.

This menu can only be set when regulation is stopped, i.e. “r12” is set to 0.

o61

Appl. Mode

Access code 2 (Access to adjustments)

There is access to adjustments of values, but not to configuration settings. If the

settings in the controller are to be protected with an access code you can set a

numerical value between 0 and 100. If not, you can cancel the function with setting 0.

If the function is used, access code 1 (o05)

must also

be used.

o64

Acc. code 2

Save as factory setting

With this setting you save the controller’s actual settings as a new basic setting

(the earlier factory settings are overwritten).

o67

-

Digital input signal - DI3 Switch signal

The controller has a digital input 3 which can be used for one of the following

functions:

Off: The input is not used.

1) Status display of the switch function

2) Door function. When the input is open it signals that the door is open. The refrig-

eration and the fans are stopped and light turn on. When the time setting in “A04”

has passed, an alarm will be issued. The cooling is restarted when the time in o89

has passed.

3) Door alarm. When the input is open it signals that the door is open. When the time

setting in “A04” is passed an alarm will be given.

4) Defrost. The function is started with a pulse signal. (see also o37)

5) Main switch. Regulation is carried out when the input is closed, and regulation is

stopped when the input is open.

6) Night operation. When the input closed, there will be regulation for night

operation.

7) Thermostat band changeover. Switch to thermostat 2 (r21) when the input

is closed.

8) Not used.

9) Not used.

10) Case cleaning. The function is started with a pulse signal. See also description

on page 5.

11) Forced refrigeration at hotgas defrost when the input is closed.

12) Night cover. Pulse signal activates night blind

13) Not used

14) Forced closing when input is interrupted.

15) Appliance shutdown when input is closed.

16) Light. DO3 pulls when the input is closed.

17) Extra light. DO4 pulls when the input is closed.

18) Cancel defrost cycle. All defrost cycles are cancelled when the input is closed.

19) Override light (pulse signal)

o84

DI3 config.