AK-CT

450A

User

Guide RS8GR602 © Danfoss 2016-10

21

Delay of a DI1 alarm

A cut-out/cut-in input will result in alarm when the time delay has been passed.

The function is defined in o02.

A27

AI.Delay DI1

Delay of a DI2 alarm

A cut-out/cut-in input will result in alarm when the time delay has been passed.

The function is defined in o37

A28

AI.Delay DI2

Signal to the alarm thermostat

Here you have to define the ratio between the sensors which the alarm thermostat

has to use. S3, S4 or a combination of the two.

With setting 0% only S3 is used. With 100% only S4 is used.

(The setting also applies to a possible B section - S3B, S4)

A36

Alarm S4%

Time delay on S6 (product sensor) for pull-down

(long alarm delay)

This time delay is used for start-up, during defrosting, immediately after a defrost and

after an appliance clean.

A change is carried out to standard time delay (A26) when the temperature has

reached below the set upper alarm limit.

The time delay is set in minutes.

A52

PullD del.S6

Alarm delay (short alarm delay on section B air temperature)

A timer function starts if the top or bottom alarm limit is exceeded. The alarm will first

becomes active when the set delay time has been exceeded.

The time delay is set in minutes.

A53

AI.Delay S3B

Reset alarm

EKC error

Compressor

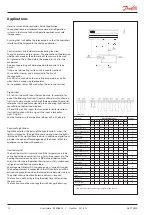

Compressor control

The compressor relay works in conjunction with the thermostat. When the

thermostat calls for refrigeration the compressor relay be operated.

Running times

To prevent irregular operation, values can be set for the time the compressor is to run

once it has been started. And for how long it at least has to be stopped.

The running times are not observed when defrosts start.

Min. ON-time (in minutes)

c01

Min. On time

Min. OFF-time (in minutes)

c02

Min. Off time

Time delay for couplings of two compressors

Settings indicate the time that has to elapse from the first relay cuts in and until

the next relay has to cut in.

c05

Step delay

u58 comp1/LLSV

Here you can read the status of the

compressor relay.

Defrost

Defrost control

The controller contains a timer function that is zeroset after each defrost start.

The timer function will start a defrost if/when the interval time is passed.

The timer function starts when voltage is connected to the controller, but it is

displaced the first time by the setting in d05.

If there is power failure the timer value will be saved and continue from here when

the power returns.

This timer function can be used as a simple way of starting defrosts, but it will always

act as safety defrost if one of the subsequent defrost starts is not received.

The controller also contains a real-time clock. By means of settings of this clock and

times for the required defrost times, defrost can be started at fixed times of the day.

Defrost start can also be accomplished via data communication, via contact signals or

manual start-up.

All starting methods will function in the controller. The different functions have to be

set, so that multiple defrosts are avoided..

Defrost can be performed using electricity, hot gas, naturally or brine.

The actual defrost will be stopped based on time or temperature with a signal from

a temperature sensor.

Defrost method

Here you set whether defrost is to be accomplished with electricity, gas, "air" or brine.

During defrost the defrost relay will be cut in.

d01

Def. method

0 = non. 1 = El. 2 = Gas. 3 = Brine.

4 = Air.

Defrost stop temperature

The defrost is stopped at a given temperature which is measured with a sensor

(the sensor is defined in d10).

The temperature value is set.

d02

Def. Stop Temp